A research team affiliated with UNIST has achieved a groundbreaking milestone by developing an adhesive that can be easily and cleanly detached at high temperatures. Led by Professor Dong Woog Lee and his research team in the School of Energy and Chemical Engineering at UNIST, this innovative breakthrough holds significant potential for revolutionizing waste treatment processes and promoting a more sustainable environment.

In the pursuit of effective recycling methods, it is essential to disassemble materials by removing adhesives used in packaging. However, traditional removal processes often rely on environmentally unfriendly harsh solvents that contribute to additional pollution concerns. To address this challenge, the research team focused on developing functional adhesive materials capable of being removed without the use of such solvents.

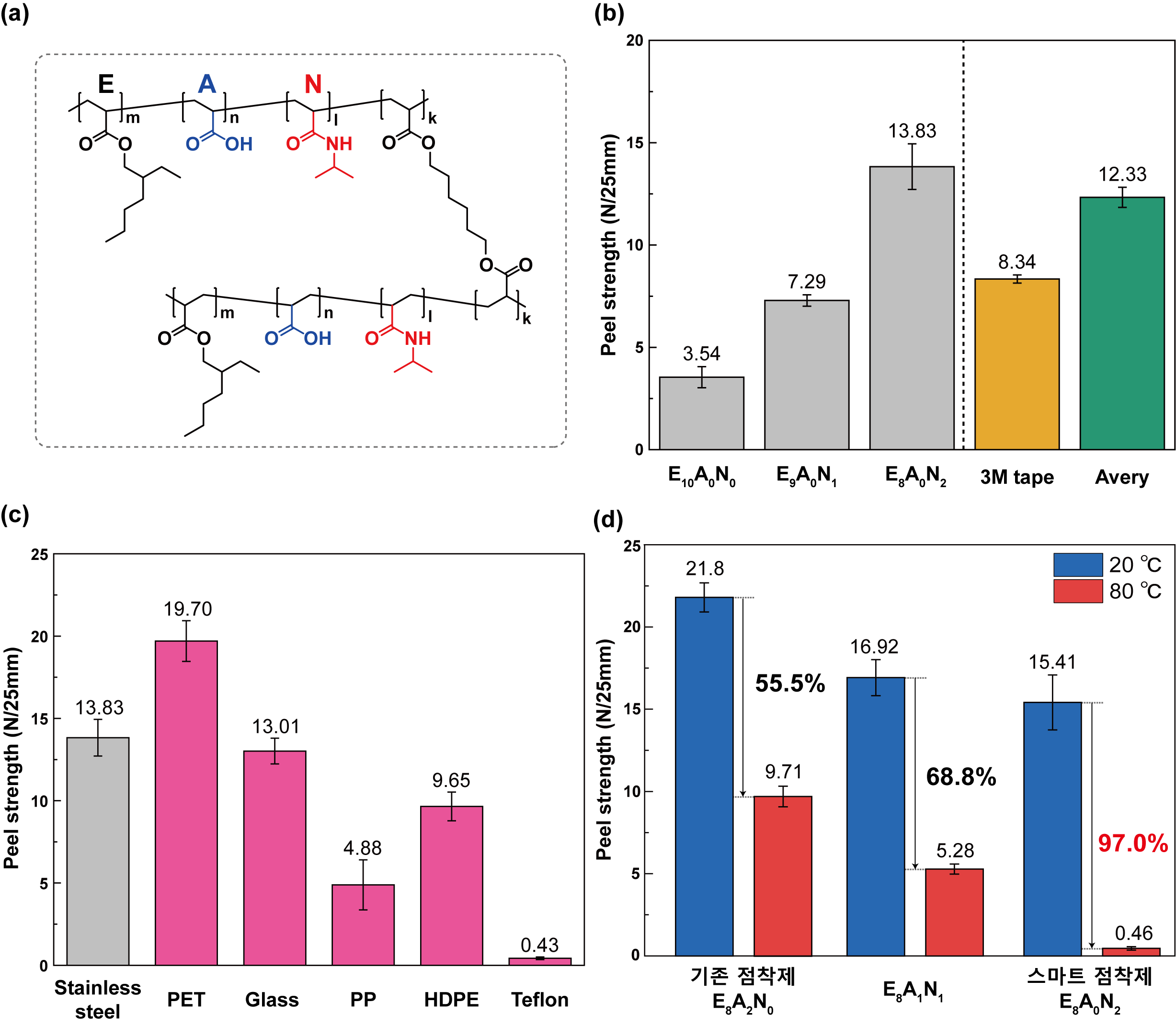

Through their extensive study, the researchers successfully synthesized thermo-switchable pressure-sensitive adhesives (PSAs) using stimuli-responsive polymers. These remarkable PSAs exhibit robust initial adhesion under normal conditions but undergo a dramatic reduction in adhesion when exposed to high temperatures. The peel strength of these thermo-switchable PSAs decreased by approximately 97% upon heating, facilitating easy detachment without leaving any residue behind.

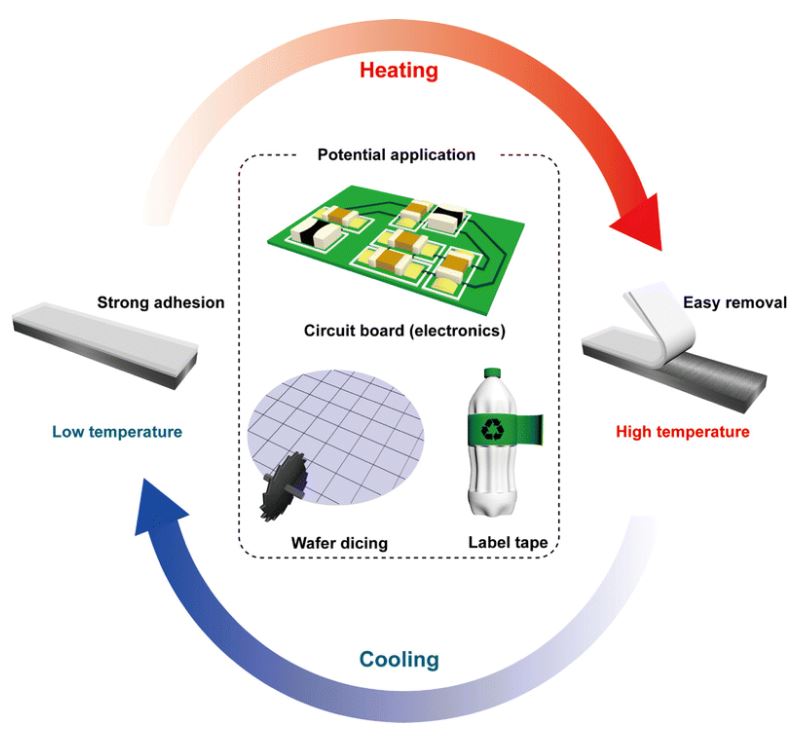

Figure 1. Potential applications of thermo-switchable PSA. Thermo-switchable PSA can be used in various industrial applications, such as circuit boards for electronics, wafer dicing, and label tapes. At low temperatures, it exhibits a high adhesion strength, which drastically decreases with increasing temperature, resulting in easy removal from substrates.

Notably, the researchers demonstrated reversible adhesion behavior of the thermo-switchable PSAs during repeated heating and cooling cycles—highlighting their potential for enhanced reusability and recyclability of valuable materials. By harnessing these novel adhesives as alternatives, it becomes possible to minimize reliance on toxic chemicals for adhesive removal while actively contributing towards building a more sustainable future.

This groundbreaking achievement paves the way for advancements in waste treatment processes across various industries where clean detachment is crucial. According to the research team, their work provides valuable insights into designing eco-friendly solutions to tackle material disassembly challenges effectively.

Figure 2. Molecular structure and adhesive performance of the synthesized PSAs. (a) Molecular structure of the synthesized thermo-switchable PSAs. (b) The 180° peel strength of NIPAM contents and conventional PSA films. Effects of (c) various types of substrates and (d) thermal annealing time on the 180° peel strength.

“Our development of an easily detachable adhesive at high temperatures opens up new avenues for improving waste treatment processes and promoting sustainability,” noted the research team. “By eliminating the need for harsh solvents, we can reduce environmental impact and enhance reusability of valuable materials.”

Published in the May 2023 issue of Materials Horizons, this work has been supported by the Korea Research Foundation (NRF), the Korea Institute of Industrial Technology Evaluation Management (KEIT), the Institute of Civil-Military Technology Cooperation (ICMTC), as well as the 2023 research fund of UNIST.

Journal Reference

Jeonguk Hwang, Daegyun Lim, Geonwoo Lee, et al., “Ambient air-operated thermo-switchable adhesion of N-isopropylacrylamide-incorporated pressure sensitive adhesives,” Mater. Horiz., (2023)