In order to accelerate the commercialization of perovskite solar cell technology, research activities are being conducted in an attempt to gain further improvement in their cost, efficiency and reliability. Among many, tandems cell technology has emerged as the most promising approach to push the limits of conventional silicon solar cells.

A recent study, led by Professor Kyoung Jin Cho in the School of Materials Science and Engineering at UNIST has demonstrated a novel two-terminal perovskite/silicon mechanical tandem solar cell, fabricated by bonding a silicon cell upside down on a perovskite cell using a transparent conductive adhesive (TCA).

The new solar cell achieved high-efficiency by using “silicon” and “perovskite” as a light absorption layer, thus simplified the manufacturing process by introducing a transparent conductive adhesive layer at the connection of the two layers. The manufacturing process has been simplified, and the expectation for commercialization has also increased.

A solar cell is an electronic device that produces electricity using the flow of electrons that appear when semiconductors absorb solar energy. Therefore, how much solar energy is converted into electricity (efficiency) depends largely on the materials that make up a solar cell. Each material has its own range of solar wavelengths. Waste or unused energy is lost or discarded at each step as heat.

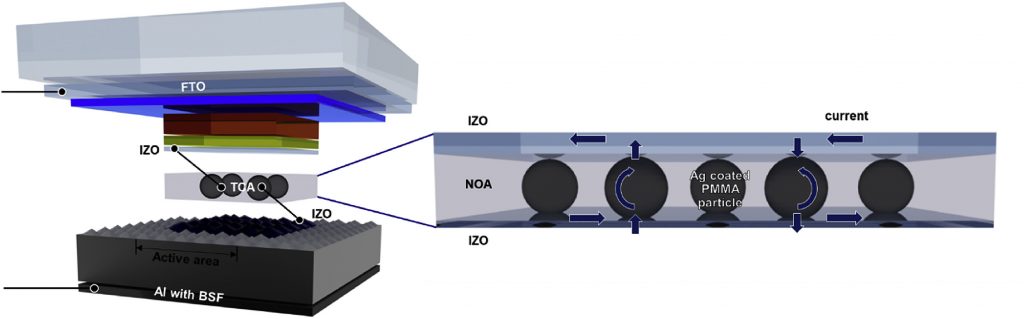

Tandem solar cells use two or more materials as the light absorption layer. Since the Solar wavelengths that each material accepts are different, there is a lot of energy that can be absorbed, thus the efficiency can be improved. However, the issue here is that this connects different light absorption layers. The problem is the way in which the different light absorbing layers are connected, because the energy loss also takes place between them. Previously, tandem solar cells were manufactured by stacking perovskite thin films on silicon solar cells. However, in this case, the perovskite thin film is difficult to properly coat due to the pyramid structure of the silicon substrate made to increase light absorption.

In this study, a simple method of mechanically attaching a completed silicon solar cell and a perovskite solar cell was proposed. Because the TCA fills well between the pyramid structures on the silicon substrate, the two layers are seamlessly connected. In addition, silver (Ag) coated polymer nanoparticles inside the conductive adhesive layer helped electrons move well between silicon and perovskite.

“It is meaningful to develop an attached tandem solar cell, unlike the conventional tandem solar cell with stacked structure,” says In Young Choi in the School of Materials Science and Engineering at UNIST, the first author of this study. “We have observed that the TCA effectively connects the different light absorbing layers.”

“With the new method, it is much easier to build than stacked tandem solar cells,” says Dr. Kuen Kee Hong from Shinsung E&G Co., Ltd.

The research team demonstrated 19.40% efficient two-terminal mechanical-perovskite/silicon-tandem devices with a transparent conductive adhesive by optically controlling the refractive index profile and perovskite absorbing layer thickness. According to the research team, the tandem cell technology in this study is expected to change the paradigm of future solar-cell technologies with such advantages as a minimal modification to the existing silicon cell structure, easy current matching technology, long-term stability, and potential high efficiency of >24%.

The findings of this study have been published in the online version of the journal, Nano Energy on August 22, 2019. It has been supported by the Korea Institute of Energy Technology Evaluation and Planning (KETEP) and the 2019 Research Fund of KOREA East-West Power Co., Ltd.

Journal Reference

In Young Choi et al., “Two-terminal mechanical perovskite/silicon tandem solar cells with transparent conductive adhesives”, Nano Energy, (2019).