A research team, affiliated with UNIST and Samsung Advanced Institute of Technology (SAIT), has unveiled a new battery technology, capable of powering an electric vehicle for over 1,000km on a single charge. That is longer than the distance between Seoul and Busan in a round trip.

Professor Dong-Hwa Seo (School of Energy and Chemical Engineering, UNIST), in collaboration with SAIT researchers, proposed a new strategy that could extend battery cycle life, one of the most difficult issues hampering the commercial development of lithium–air batteries. That was to replace the organic electrolytes with the ceramic electrolyte materials. In recognition of that importance, their findings have been featured on the cover page of Advanced Energy Materials, published on October 13, 2020.

Their findings have been featured as a cover page of the October 2020 issue of Advanced Energy Materials.

Lithium–air batteries (LABs) possess great potential for efficient energy storage applications, as they can store up to 10 times as much power as conventional lithium–ion batteries (LIBs), used in EVs and other electronic devices. Besides, these batteries use ambient air as electrode materials, which aids in reducing the total vehicle weight. This is why LABs have been emerged as a promising alternative to LIBs, suitable for the next-generation lightweight long-range EVs.

Despite this promise, one of the most difficult issues hampering the commercial development of LABs is the poor cycle life due to the active oxygen generated during battery operation. The research team has exteded the battery cycle life significantly by replacing the organic electrolytes with high-performance ceramic electrolyte materials. Through this, they have greatly improved the charge/discharge cycle life, from 10 times to 100 times.

Besides, unlike the existing ceramic materials that exhibit high ionic conductivity, the newly-developed material is considered promising since it presents high ionic conductivity, together with high electronic conductivity. This will enable the widespread use of this material in various components of a battery.

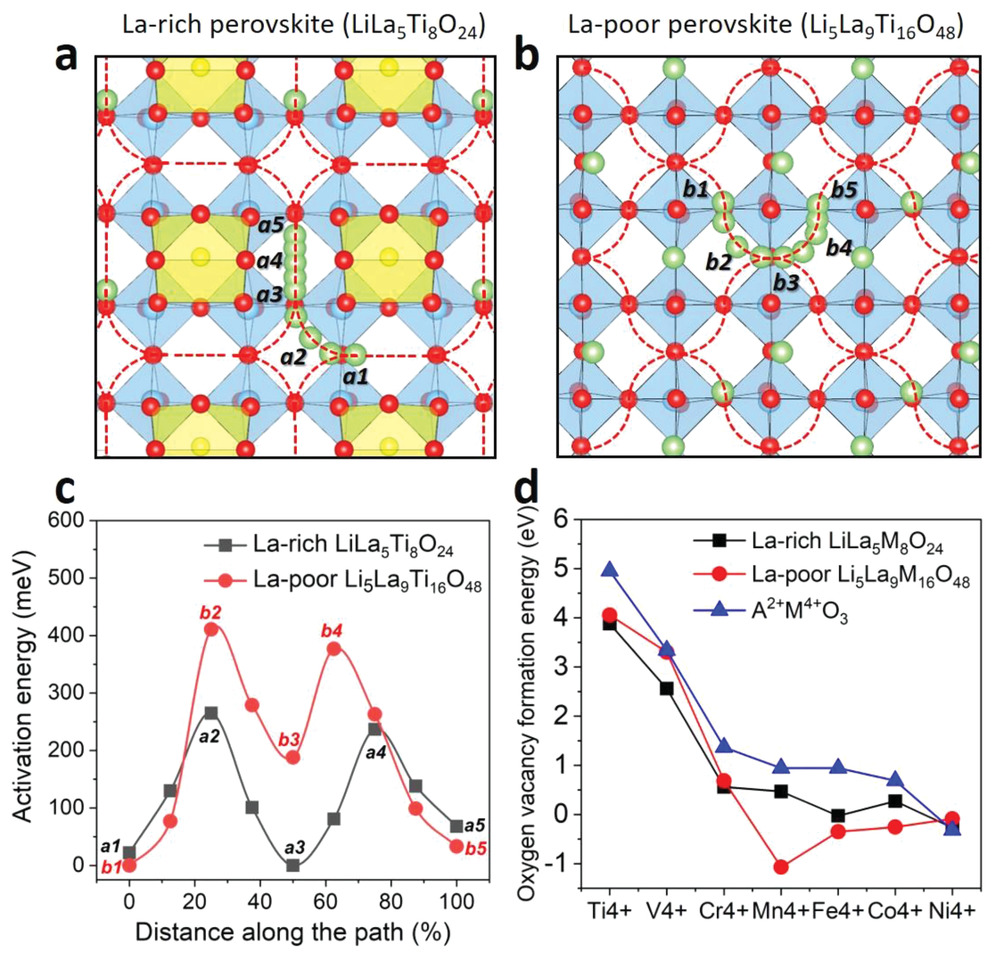

In their study, the research team discovered a novel material with high ionic and electronic conductivities via the quantum mechanical method based on Density Functional Theory (DFT). Through this, they developed the ionic–electronic conductors (MIECs) of perovskite LixLayMO3−δ for carbon‐free cathode of Li–air batteries. The designed perovskites of Li0.34La0.55MnO3−δ experimentally prove to have high electronic and Li‐ion conductivities, and when applied in a carbon‐free cathode of a Li–air cell, they deliver superior reversibility over 100 charge/discharge cycles while avoiding the degradation associated with carbonaceous materials.

“This strategy opens a new avenue in designing Li‐conducting MIEC and reversible Li–air batteries in an effective way,” says Professor Seo, Corresponding author of the study.

This study has been carried out with the support of Samsung Electronics, UNIST Future-Leading Research Initiative, and the Supercomputing Center through the Korea Institute of Science and Technology Information (KISTI).

Journal Reference

Sang Bok Ma, Hyuk Jae Kwon, Mokwon Kim, et al., “Mixed Ionic–Electronic Conductor of Perovskite LixLayMO3−δ toward Carbon‐Free Cathode for Reversible Lithium–Air Batteries,” Advanced Energy Materials, (2020).