UNIST hosted a collaborative workshop with the Fraunhofer ICT (Institute for Casting, Composite, and Processing Technology) in Germany on July 16, focusing on advancing composite material technologies. The event brought together industry leaders and researchers to explore new avenues for international cooperation and innovation.

The ‘Open House on Composites’ event was attended by over 100 representatives from leading Korean manufacturing companies across the automotive, aerospace, and shipbuilding sectors. The workshop featured live demonstrations of cutting-edge composite material prototypes and detailed technical explanations, illustrating the entire development process from laboratory research to industrial application.

Professor Young-Bin Park, Director of the FIP@UNIST Center, presented UNIST’s latest developments in ultra-lightweight components for autonomous vehicles. Fraunhofer ICT showcased its expertise in fiber-reinforced composite design and high-speed molding techniques.

Additionally, Simutrans, a German company specializing in structural analysis and simulation, demonstrated real-time comparisons between manufactured products and simulation results, highlighting the precision of their analytical tools.

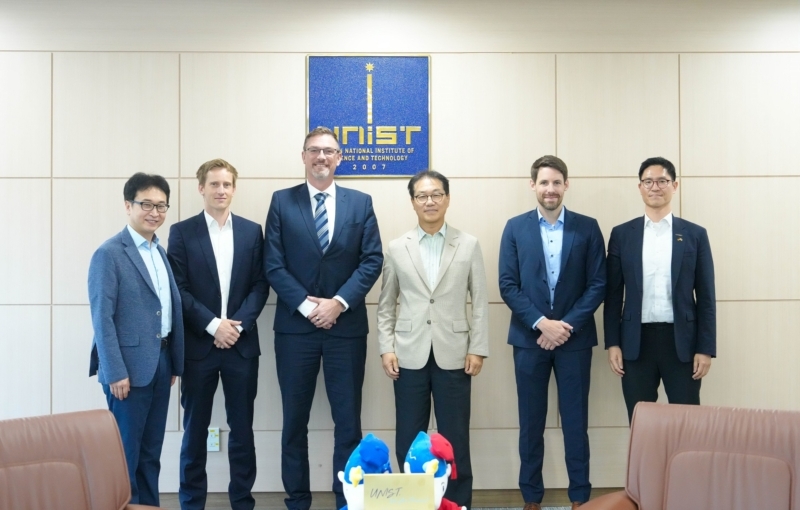

UNIST President Chong Rae Park and Director Frank Henning of Fraunhofer ICT engaged in a productive discussion, exploring partnership opportunities to combine Korea’s strengths in fundamental science with Germany’s applied engineering expertise. President Park emphasized, “Our technology does not stay confined to the lab. We are committed to translating research into practical solutions that benefit industry, and we will work closely with our partners to ensure this transition.”

During the seminar, the latest trends in composite material development at Fraunhofer ICT were introduced. Dr. Dominic Dür, CEO of Simutrans, presented case studies on optimized composite component design through simulation, demonstrating how virtual testing enhances product performance.

The seminar also featured in-depth presentations from Director Hennig and Research Planning Officer Bjoern Beck, focusing on state-of-the-art advances in composite materials.

Participants observed firsthand how simulation-based design and structural analysis data can improve manufacturing quality, with particular interest in UNIST’s own composite analysis technologies.

Fraunhofer is one of Europe’s largest applied research organizations, renowned for its leadership in materials science and manufacturing technology. Its ICT division specializes in composite molding, and in 2016, established the FIP@UNIST (Fraunhofer Innovation Platform) branch—the first of its kind in Korea—under official German accreditation. The center boasts some of the world’s top-tier expertise in composite design and high-speed molding.

The event also featured demonstrations of proprietary technologies developed by FIP@UNIST, showcasing real-time manufacturing and structural analysis processes, effectively translating laboratory innovations into industry-ready solutions.

Professor Park stated, “UNIST is committed to co-developing advanced composite materials with Fraunhofer ICT to meet industry needs. Moving forward, we aim to enhance AI-driven manufacturing technologies and diversify application sectors, strengthening Korea’s manufacturing competitiveness through ongoing industry collaboration.”