As electric vehicles (EVs) and smartphones increasingly demand rapid charging, concerns over shortened battery lifespan have grown. Addressing this challenge, a team of Korean researchers has developed a novel anode material that maintains high performance even with frequent fast charging.

A collaborative effort by Professor Seok Ju Kang in the School of Energy and Chemical Engineering at UNIST, Professor Sang Kyu Kwak of Korea University, and Dr. Seokhoon Ahn of the Korea Institute of Science and Technology (KIST) has resulted in a hybrid anode composed of graphite and organic nanomaterials. This innovative material effectively prevents capacity loss during repeated fast-charging cycles, promising longer-lasting batteries for various applications.

During battery charging, lithium ions (Li-ions) move into the anode material, storing energy as Li atoms. Under rapid charging conditions, excess Li can form the so-called dead lithium deposits on the surface, which cannot be reused. This buildup reduces capacity and accelerates battery degradation.

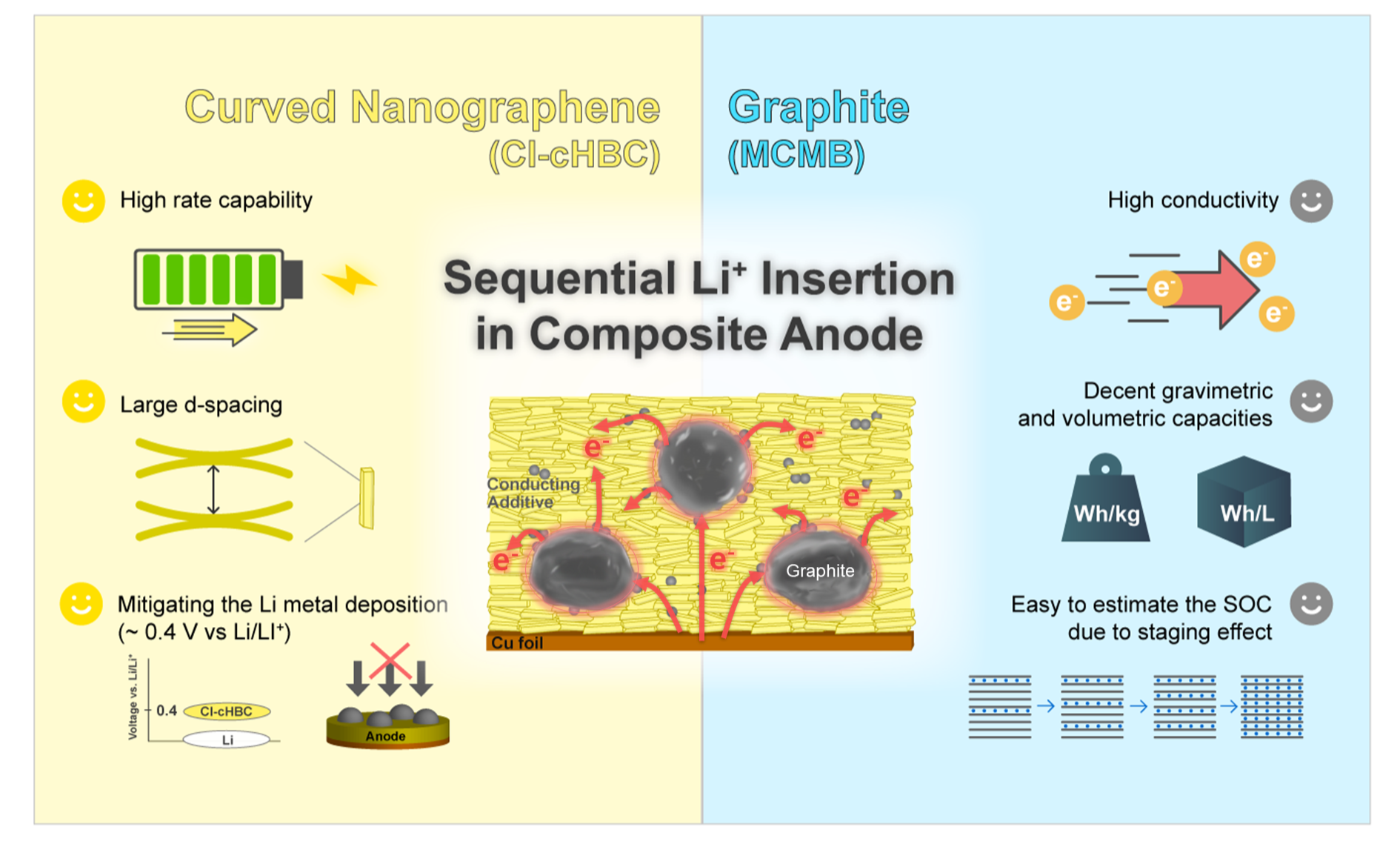

The research team designed a structural solution to this problem. Their hybrid anode features commercially used graphite particles (mesocarbon microbeads, MCMB) uniformly embedded within bent, curved nanosheets of chlorinated contorted hexabenzocoronene (Cl-cHBC). The unique curved nanosheets create larger interlayer spaces and nanoscale channels, allowing Li-ions to pass through more quickly and efficiently.

Figure 1. Schematic representation of the synergistic effect between Cl-cHBC and MCMB graphite in the hybrid anode.

When blended in equal parts, these two materials facilitate a sequential Li-ion insertion process where ions first enter the nanosheets and then move into the graphite. This staged insertion prevents the formation of dead lithium, enabling fast charging without capacity loss, as confirmed through theoretical simulations.

Experimental tests demonstrated that this hybrid anode delivers over four times the capacity of conventional graphite under high-rate charging conditions (4 A/g). The staged insertion process allows for higher Li storage and improved cycle stability.

Full-cell testing paired the hybrid anode with a high-performance cathode (NCM811), where it retained 70% of its initial capacity after over 1,000 charge-discharge cycles. When assembled into pouch cells, the hybrid anode demonstrated stable operation over 2,100 cycles with a Coulombic efficiency of 99%, showcasing its potential for real-world applications.

The researchers highlight that this simple, scalable fabrication process is compatible with existing battery manufacturing infrastructure. Furthermore, leveraging the chemical versatility of curved nanosheets opens avenues for developing sodium-ion batteries and other energy storage systems.

The team emphasizes that the sequential Li-ion insertion mechanism uncovered in this study offers a promising design principle for next-generation batteries that require both rapid charging and long-term stability.

This groundbreaking research was published online in Advanced Functional Materials on September 10, 2025. It was supported by the National Research Foundation (NRF) of Korea, UNIST, and KIST.

Journal Reference

Hyunji Cha, Minsung Kang, Seung Hak Oh, et al., “Curved Nanographene–Graphite Hybrid Anodes with Sequential Li+ Insertion for Fast-Charging and Long-Life Li-Ion Batteries,” Adv. Funct. Mater., (2025).