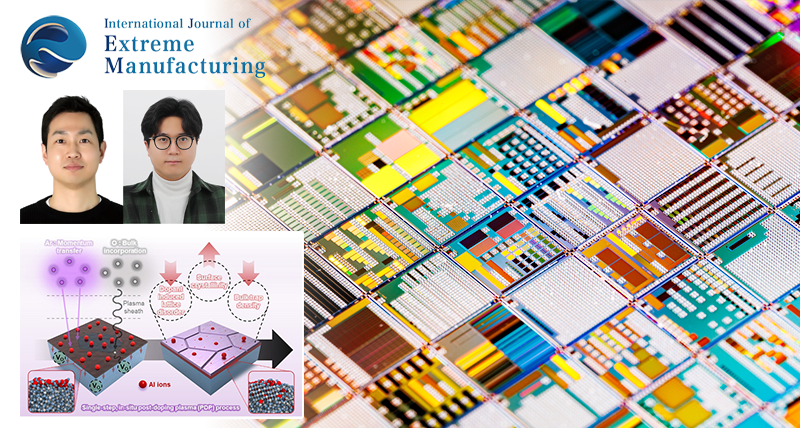

A joint research team, led by Professor Byungjo Kim of the Graduate School of Semiconductor Materials and Devices Engineering at UNIST and Professor Jihwan An of the Department of Mechanical Engineering at POSTECH has pioneered a groundbreaking fabrication technology to improve the performance of semiconductor devices.

All electronic devices—from smartphones and laptops to supercomputers—require small storage spaces to temporarily hold data. Memory semiconductors such as DRAM play a crucial role in this function. However, as these devices become increasingly miniaturized and fabricated with thinner films, issues such as electrical leakage and reduced stability have become significant challenges.

Within DRAM, the capacitor—a tiny component—acts as a container for electrical charge. To effectively store charge, this container must be lined with a high-quality dielectric layer that can withstand high electric fields. Among candidate materials, aluminum-doped titanium dioxide (Al-doped TiO₂, or ATO) stands out due to its high dielectric constant and excellent leakage suppression. Nonetheless, conventional atomic layer deposition (ALD) methods for fabricating ATO often cause lattice disorder and oxygen vacancies, leading to material instability and increased leakage currents.

To address these limitations, the research team introduced a novel Post-Doping Plasma (PDP) process. After depositing the TiO₂ dielectric layer via ALD and subsequently coating it with an ultrathin aluminum oxide layer, the team exposed the film to a plasma composed of argon (Ar) and oxygen (O₂). This plasma treatment transferred energy to the film’s surface, facilitating atomic-scale migration of aluminum dopants and reordering of the crystal lattice. Simultaneously, oxygen vacancies—defects that can cause electrical leakage—were effectively filled.

Experimental results demonstrated that DRAM capacitors treated with this PDP process exhibited approximately 30% higher dielectric constants and up to nearly 40 times lower leakage currents. Further simulations revealed that energetic Ar ions in the plasma delivered targeted energy to the dielectric surface, enabling aluminum atoms to settle into their proper lattice positions, thus restoring crystallinity at the atomic level. This achievement not only enhances device performance but also marks a significant advance in understanding the atomic interactions involved in plasma-material interactions within semiconductor fabrication processes.

Professor Jihwan An of POSTECH emphasized, “The atomic-layer process developed in this study can be applied broadly—not only to DRAM but also to next-generation electronic devices and energy storage systems. This technology will strengthen Korea’s position in the global semiconductor industry.”

Professor Kim of UNIST added, “Understanding the fundamental interplay between plasma and materials at the atomic scale is a major scientific breakthrough. Our findings will contribute to elevating Korea’s competitive edge in advanced semiconductor manufacturing.”

This research has been published in the September 2025 edition of International Journal of Extreme Manufacturing, a leading international journal in the field of manufacturing science. It was supported by the Samsung Electronics Co., Ltd., the Basic Science Research Program through the National Research Foundation of Korea (NRF) funded by the Ministry of Education, the Korea Institute for Advancement of Technology (KIAT), and the Ministry of Trade, Industry and Energy (MOTIE). The computations were performed at the Korea Institute of Science and Technology Information (KISTI) National Supercomputing Center.

Journal Reference

Gyuha Lee, Youngmin Sunwoo, Hyong June Kim, et al., “In-situ post-doping plasma process during atomic layer deposition of Al-doped TiO2 for sub-nanometer lattice ordering and defect annihilation,” Int. J. Extrem. Manuf., (2025).