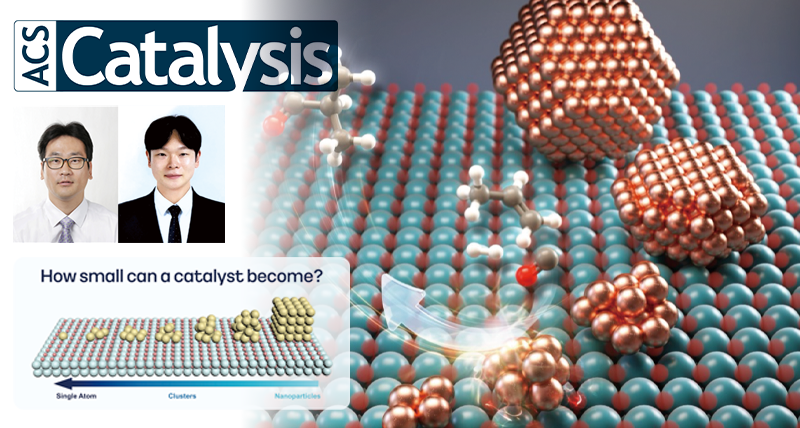

Recent research has demonstrated that a rhodium (Rh) cluster of an optimal, intermediate size—neither too small nor too large—exhibits the highest catalytic activity in hydroformylation reactions. Similar to the concept of finding the ‘just right‘ balance, the study identifies this so-called ‘Goldilocks‘ size as crucial for maximizing catalyst efficiency.

Led by Professor Kwangjin An from the School of Energy and Chemical Engineering at UNIST, in collaboration with Professor Jeong Woo Han from Seoul National University, the research demonstrates that when Rh exists as a cluster—comprising about ten atoms—it outperforms both single-atom and nanoparticle forms in reaction speed and activity.

Hydroformylation is a vital industrial process used for producing raw materials for plastics, detergents, and other chemicals. Currently, many Rh catalysts are homogeneous—dissolved in liquids—which complicates separation and recycling. This challenge has driven efforts to develop solid, heterogeneous Rh catalysts that are easier to recover and reuse.

The size of Rh particles has long been recognized as a key factor influencing catalytic performance. The prevailing assumption was that single-atom catalysts (SACs)—where individual rhodium atoms are evenly dispersed—would be the most effective, as they maximize the number of active sites on the surface.

However, this study challenges that assumption. The team found that rhodium clusters—aggregates of roughly ten atoms—offer a remarkable combination of high activity and stability. Supported on alumina (Al₂O₃), these clusters demonstrated significantly enhanced catalytic performance.

By preparing catalysts with varying rhodium loadings (from 0.05% to 5% by weight), the researchers produced different catalyst types—single atoms, clusters, and nanoparticles—and analyzed their behavior through a combination of laboratory experiments and theoretical calculations.

The findings revealed that the improved performance stems from how these clusters interact with carbon monoxide (CO), a key reactant in hydroformylation. The rate-limiting step involves CO inserting into the intermediate, and rhodium clusters hit the sweet spot by binding CO strongly enough to facilitate this step without hindering subsequent reactions. In contrast, single-atom catalysts bind CO too tightly, blocking progress, while nanoparticles bind CO too weakly, limiting reactivity.

This research offers valuable insights into how catalyst size and electronic properties influence reaction pathways. It lays a solid foundation for designing stable, high-performance solid rhodium catalysts that optimize metal-support interactions, redox stability, and cluster integrity.

The findings of this research have been featured as the cover story in ACS Catalysis on December 19, 2025. The study has been supported by the National Research Foundation of Korea (NRF) and the Ministry of Science and ICT (MSIT).

Journal Reference

Daewon Oh, Miyeon Kim, Hojeong Lee, et al., “Rh Cluster Catalysts with Enhanced Catalytic Activity: The ‘Goldilocks Rh Size’ for Olefin Hydroformylation,” ACS Catalysis, (2025).