A research team, affiliated with UNIST has unveiled a highly-flexible and durable electrode using the dream material, graphene. Using this graphene-based electrode, the research team made it possible to make organic solar cells (OSCs) that can achieve the highest power conversion efficiency (PCE). The proposed electrode is promising for use in various optoelectronic devices requiring high efficiency and flexibility.

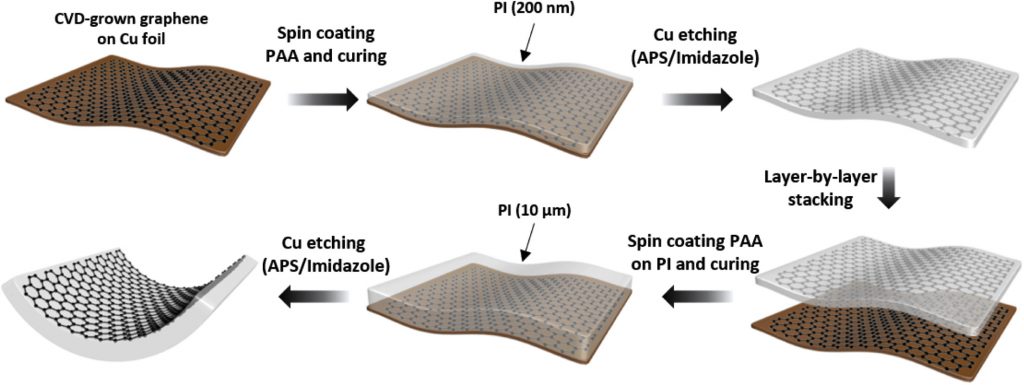

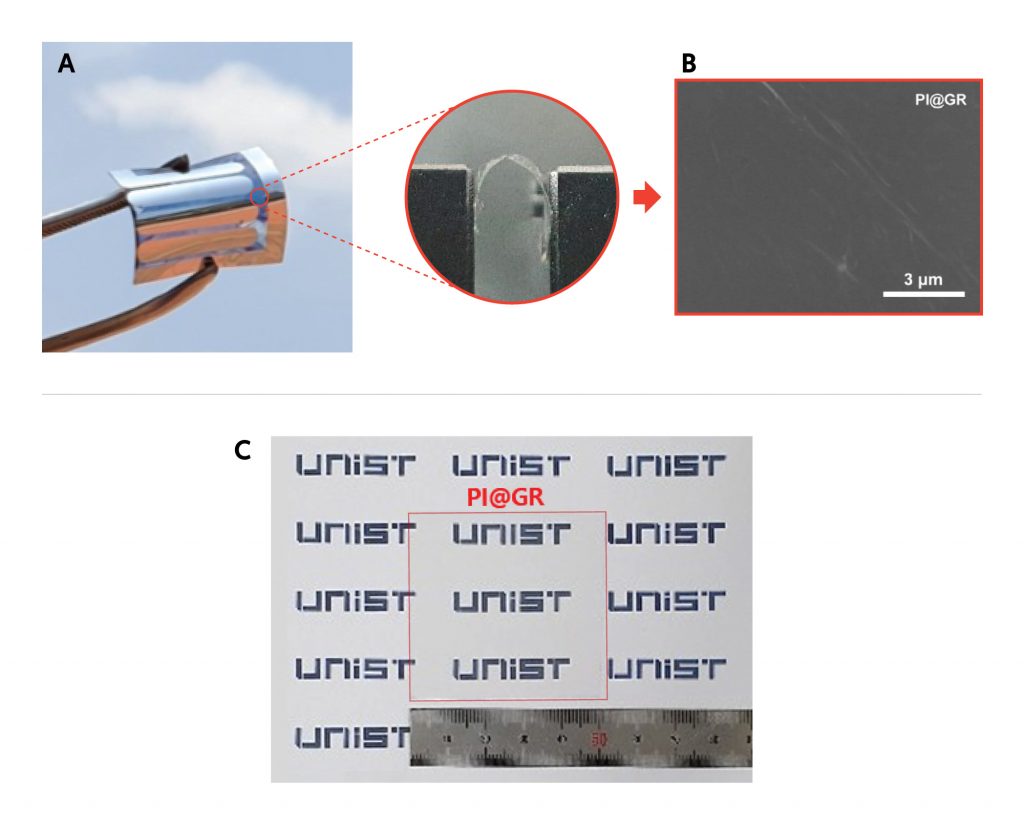

A research team, led by Professor Hyesung Park and Professor Changduk Yang in the School of Energy and Chemical Engineering at UNIST has demonstrated a highly flexible and durable graphene-based electrode through direct integration of thermally stable polyimide (PI) on graphene, where PI serves a bifunctional role as a carrier film for graphene transfer and substrate for the graphene. The new manufacturing technique was devised to not impair the excellent electrical conductivity and durability of graphene, thereby compensating for the disadvantages of the existing graphene electrodes.

The basic structure of commercial solar cells is composed of several layers: ‘Photoactive layers’ that generate electrons with the help of sunlight, ‘electrodes’ that serve as pathways for electrons, and ‘substrates’ that maintain the entire cell structure. Organic solar cells (OSCs) have been regarded as the next-generation solar cells due to their merits, including lightweight and high mechanical flexibility. However, with the existing electrodes, it has been difficult to realize high-efficiency flexible and lightweight OSCs.

Graphene has received much attention as a promising flexible transparent electrode owing to its outstanding optical and electrical properties together with mechanical robustness and chemical and thermal stability. As a result, it has been regarded as a promising electrode material to accelerate the commercialization of OSCs. However, since graphene is only one atom thick, a support layer is required during the transfer process to protect it from the external force. In general, polymers that do not conduct electricity are used as a support material to transfer the graphene. However, the graphene transfer process with polymer supporting layer tends to leave residues on the graphene surface and this decreases the electrical conductivity. In addition, due to the insufficient power to fix the graphene on the substrate, they may break apart when bending or repeatedly applying an external force.

Figure 1. Schematic Describing the Two-Step Fabrication Process of PI@GR

In the study, a highly flexible and durable graphene-based electrode is demonstrated through direct integration of thermally stable polyimide (PI) on graphene, where PI serves a bifunctional role as a carrier film for graphene transfer and substrate for the graphene. According to the joint research team, this approach yielded a thermally stable graphene electrode with a low sheet resistance of 83 Ω/sq enabled by a polymer residue-free graphene surface, as well as outstanding mechanical durability via improved adhesion between the graphene and PI substrate. Along with high optical transmittance over 92%, the proposed graphene-based OSCs exhibit outstanding mechanical robustness during up to 10,000 bending cycles along with a PCE of 15.2%, which is comparable to that of indium-tin-oxide-based reference device fabricated on a rigid glass substrate (15.7%).

Figure 2. Mechanical properties and durability of the graphene-based electrodes.

“Using the PI-assisted graphene electrode, flexible OSC with a PCE of 15.2% was obtained with outstanding mechanical robustness,” says Donghwan Koo (Combined M.S/Ph.D. of Energy and Chemical Engineering, UNIST), the first author of the study. “Moreover, direct integration of PI improved the durability of the graphene electrode by inhibiting delamination of the graphene under mechanical stress.”

The new polyimide-integrated graphene electrodes can be applied to other electric devices that require a high temperature process. This is because the materials used as the substrate of the existing graphene-based electrode is deformed at a high temperature, but the polyimide material can withstand a high temperature of 400 ° C or higher, thus no deformation occurs.

“The proposed electrode is promising for use in various optoelectronic devices requiring high efficiency and flexibility,” says Professor Park. “Thus, it is expected to be of great help in the development of various next-generation flexible photoelectric devices, such as high-performance LEDs and light sensors, as well as solar cells.”

The findings of this research have already been published in an online issue of Joule on April 6, 2020. This research has been supported by the National Research Foundation of Korea (NRF), the Ministry of Science, ICT, and Future Planning, and the Korea East-West Power Corporation.

Journal Reference

DonghwanKoo, SungwooJung, JihyungSeo, et al., “Flexible Organic Solar Cells Over 15% Efficiency with Polyimide-Integrated Graphene Electrodes,” Joule, (2020).