A research team, affiliated with UNIST has come up with an innovative hydrocarbon manufacturing route, using a commercially available ball-milling device. The new method has commercial potential, as it uses natural wood-derived charcoal to produce methane (CH4), the main hydrocarbon component of natural gas.

Published in the March 2022 issue of Angewandte Chemie International Edition, this breakthrough has been led by Professor Jong-Beom Baek in the School of Energy and Chemical Engineering at UNIST.

“Using the mechanical collision created by the ball-milling technique, we can easily decompose charcoal to produce methane,” said Professor Baek. “We expect that this method can even enable the production of methane from coal, a fossil fuel similar to charcoal.”

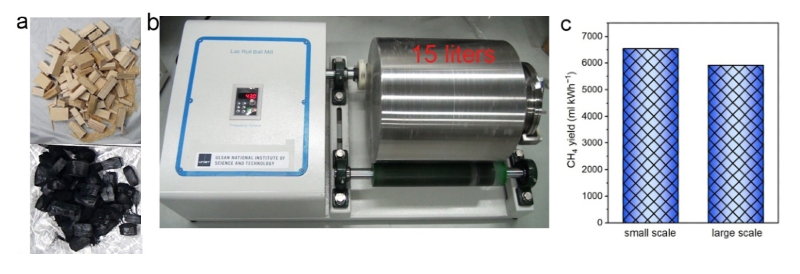

Figure 1. Large-scale carbon hydrogasification. a) Pinewood, and as-prepared charcoal after wood pyrolysis. b) Home-made roll-mill with a 15-liter container. c) Comparison between small-scale planetary mill and large-scale roll-mill.

In this study, the research team demonstrated a mechanochemical method that results in both a faster reaction rate and a new synthesis route. The reaction rate was dramatically enhanced by up to 4 orders of magnitude compared to the traditional thermal method. Simultaneously, the reaction exhibited very high selectivity (99.8% CH4, versus 80% under thermal conditions) with a cobalt catalyst, noted the research team.

Besides, their study demonstrated that this extreme increase in reaction rate originates from the continuous activation of reactive carbon species via mechanochemistry. The high selectivity is intimately related to the activation at low temperatures, at which higher hydrocarbons are difficult to form. According to the research team, this work is expected to advance studies of carbon hydrogasification and other solid-gas reactions.

“Our work introduces a new method for carbon hydrogasification, with high rates at low temperatures. The synthesized hydrocarbons are carbon-neutral,” noted the research team. “The all cycle, from biomass production to mechanochemical carbon hydrogasification (CHG) and finally methane utilization is a net-zero carbon dioxide emission process and might be partially net-negative.”

According to the research team, this is an important prospect to replace the limited carbon-positive natural gas reserves and prevent global warming. “Our findings can be used as a non-oxidative method to regenerate coke-poisoned catalysts, which is frequently required in large-scale industrial production,” noted Professor Baek. “This method not only avoids aggregation when burning the carbon due to the highly exothermic nature of the reaction but also reduces the catalyst size at the same time.”

The findings of this research have been published in the online version of Angewandte Chemie International Edition on March 14, 2022. This research has been supported by the National Research Foundation (NRF) of Korea, and the UK Brand Project of UNIST.

Journal Reference

G.-F. Han, P. Zhang, P. Scholzen, et al., “Extreme Enhancement of Carbon Hydrogasification via Mechanochemistry,” Angew. Chem. Int. Ed., (2022).

Pingback: An innovative hydrocarbon manufacturing route - Digi Tech Paradise 2022()

Pingback: An innovative hydrocarbon manufacturing route - all-news()

Pingback: An ingenious hydrocarbon production path - Mochiter Tech News()