A research team, affiliated with UNIST has announced a groundbreaking advancement in battery safety. Led by Professor Hyun-Wook Lee from the School of Energy and Chemical Engineering, the team has integrated pressure and displacement sensors into the exterior of all-solid-state batteries (ASSBs), enabling the early detection of lithium dendrite formation—a crucial precursor to potential short circuits.

All-solid-state batteries (ASSBs) are considered the next generation of energy storage technology, replacing volatile liquid electrolytes with solid electrolytes. While this advancement significantly reduces the risk of explosions and fires, the possibility of internal short circuits remains. Short circuits occur when lithium dendrites, needle-like structures, penetrate the electrolyte, potentially leading to catastrophic battery failure. Batteries employing lithium metal as the anode are particularly vulerable to dendrite growth.

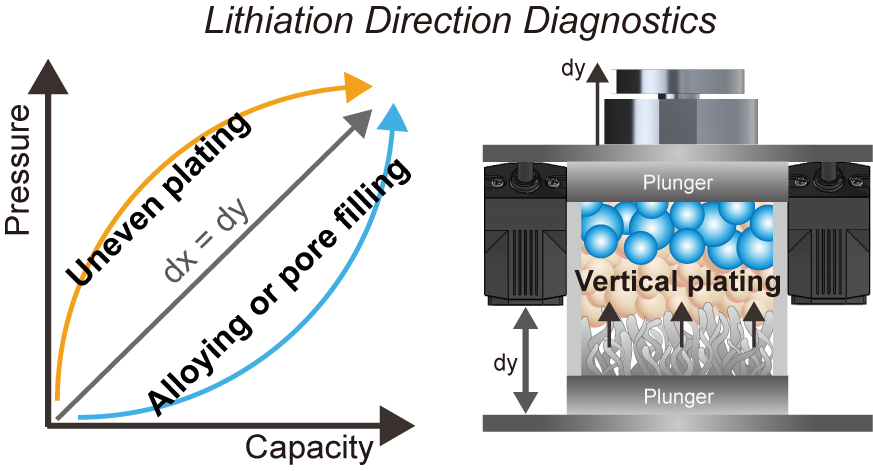

Under typical charging conditions, lithium deposits uniformly across the electrode surface. However, dendrites tend to grow vertically, disrupting this uniformity and resulting in significant risks.

To address this challenge, the research team developed a novel detection method that employs pressure and dual displacement sensors strategically attached to the battery cell. This monitoring system detects minute volume changes within the cell that occur as dendrites begin to form. Notably, the vertical growth of dendrites leads to sudden fluctuations in pressure and pronounced differences in cell thickness, as measured by sensors on either side of the cell.

Figure 1. Figure 1. Schematic illustrations and corresponding pressure increase behavior during Li plating under different conditions.

Through this analytical approach, the team also investigated specific conditions that mitigate dendrite formation. For instance, increasing the stack pressure within an assembled battery—comprised of multiple stacked cells—effectively suppresses dendrite growth. Additionally, the application of coatings made from metals, such as silver or magnesium, which exhibit high compatibility with lithium, further inhibits dendrite development.

Research findings reveal that applying a pressure exceeding 20 MPa not only fosters uniform lithium insertion into both lithium and silicon composite anodes used in commercial batteries but also achieves a remarkable Coulombic efficiency of 99.7%. This high efficiency indicates minimal lithium loss, leading to enhanced charge-discharge performance and prolonged battery lifespan.

Professor Lee explained, “Although ASSBs inherently present a safer alternative due to their non-flammable solid electrolytes, dendrite penetration through the solid electrolyte can still pose a risk of internal electrical short circuits.” He further emphasized, “Our research establishes a quantitative standard for early diagnosis of such risks, and thus real-time monitoring of lithium plating directionality and uniformity represents a significant step toward enhancing the stability and commercial viability of SSBs.”

The research findings have been published online on June 10 in ACS Energy Letters and recognized as one of the most viewed papers in the past month. The research was supported by Hyundai Motor Company, the National Research Foundation of Korea (NRF), and the Ministry of Science and ICT (MSIT).

Journal Reference

Soon-Jae Jung, Chanhee Lee, Changhyun Park, et al., “Lithiation Diagnostics by Measuring Electrochemodynamics in Solid-State Batteries,” ACS Energy Letters, (2025).