A recent study, affiliated with UNIST has introduced a novel method for the fabrication of highly transparent silver nanowires (AgNWs) that are nearly invisible to the naked eye. This flatly played down the likelihood of applying the technology to create a smart film, specialized in displaying information on glasses and preventing frost on automotive windshields.

This study has been led by Professor Jang-Ung Park in the School of Materials Science and Engineering at UNIST in collaboration with Professor Sun-Kyung Kim in the Department of Applied Physics from Kyung Hee University. In the study, the team has succeeded in engineering a ‘99% transparent metal electrode by forming an oxide film on the transparent electrode, light scattering is minimized and electrode transparency is dramatically improved.

Transparent electrodes are thin films that transmit electricity through visible light. Currently, ITO (indium tin oxide) transparent electrodes are widely used for flat displays and touch panels. In recent years, instead of instead of ITO, transparent electrodes (silver nanofibers, silver nanowires, metal grids, etc.) have been studied in which a metal is formed at a level of several micrometers (㎛) or less. However, the structured metals can sustain a very large scattering cross-section that is induced by localized surface plasmons, which often has an adverse effect on their use as transparent electrodes in displays, touch screens, and smart windows due to an issue of low clarity, according to the research team.

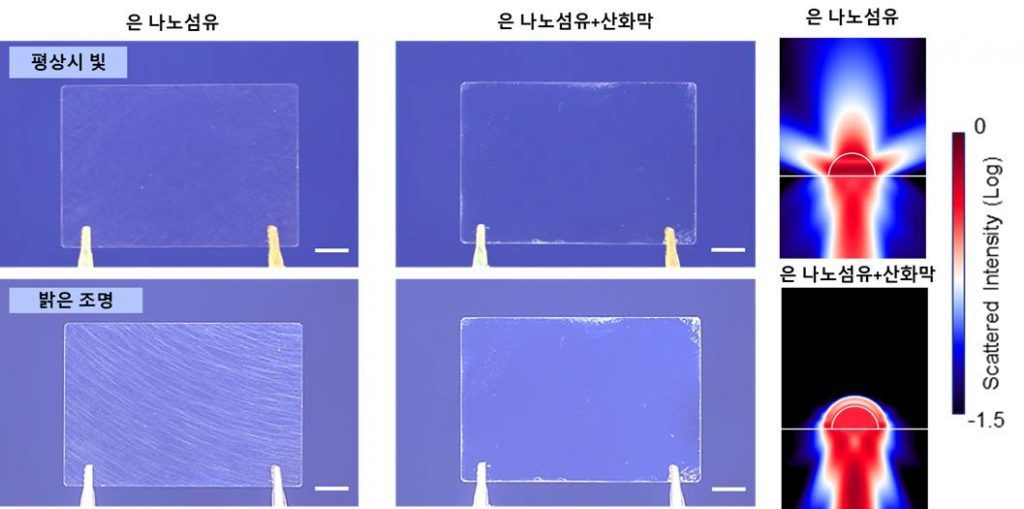

In the study, Professor Park’s team introduced an oxide film that thinly covers the metal structure to solve light scattering by the metal structure. The scattering of light by the metal changes the electrical polarity of the electrons filling the light-receiving metal (polarization). If the polarization of electrons can be induced in the direction opposite to the metal, polarization can be canceled and scattering suppression is possible. In this study, we used oxide films to challenge polarization cancellation.

The researchers placed the AgNWs with a thickness of 1 μm in a mesh structure and partially oxidized the surface to form an oxide film of 100 nanometers. Such electrodes completely inhibited the scattering of light produced by the silver nanowires and exhibited extremely high transparency of 99% when compared to the existing glasses without silver nanowires. At the same time, it also showed electric conductivity twice as high as that of the conventional ITO transparent electrode.

The team also succeeded in developing a ‘transparent heater’ for automobile glasses, using the new AgNWs. The transparent heater installed on a toy car glass, quickly removed the fogging without blocking the view.

“We expect a wider range of applications as we have addressed the important problem of light scattering in transparent electrodes,” says Professor Park. “We expect to be able to apply transparent electrodes to smart glasses, smart contact lenses, augmented reality (AR), as well as displays using transparent electrodes.”

“The newly-developed oxide-based scattering suppression technology is applicable to all metal structures as well as silver nanowires,” says Professor Kim. “In addition to transparent electrode applications, the technology will be applied to transparent cloak technology, which makes metal structures disappear from the eye.”

The findings of this study have been published as an ASAP (As Soon As Publishable) article in Nano Letters, one of the most prestigious journals in the field of materials engineering issued by the American Chemical Society.

Journal Reference

Sang-Woo Kim, et al., “A Full-Visible-Spectrum Invisibility Cloak for Mesoscopic Metal Wires,” Nano Letters, (2018).