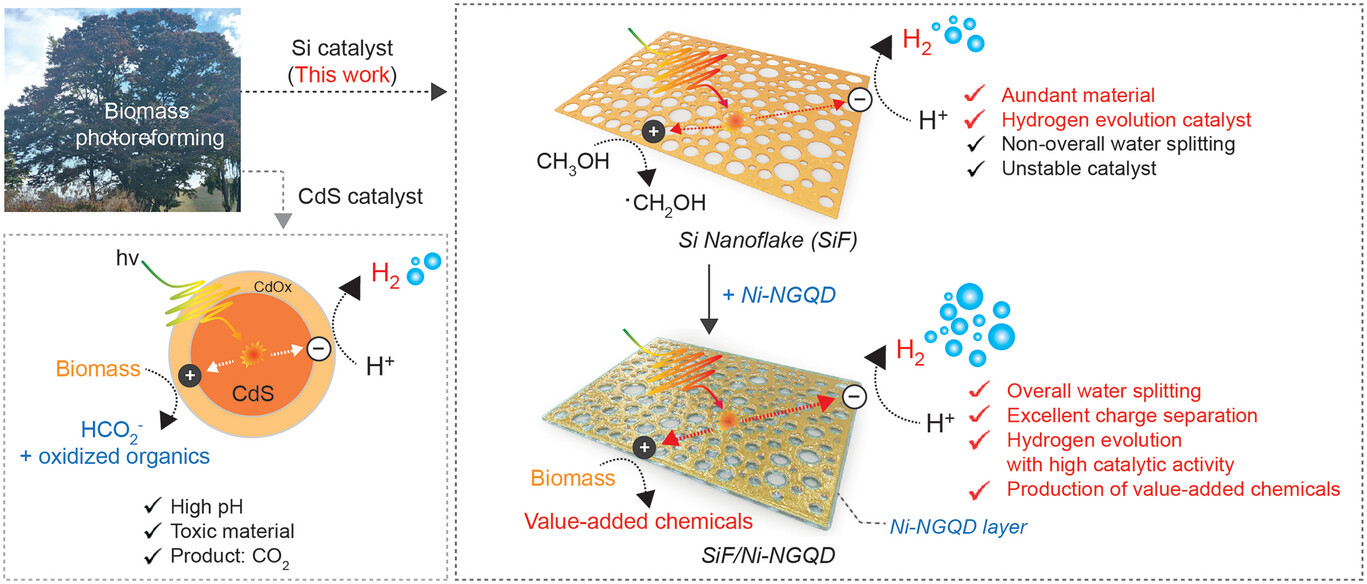

A team of researchers, led by Professor Jungki Ryu in the School of Energy and Chemical Engineering at UNIST and Professor Soojin Park from Pohang University of Science and Technology (POSTECH), have achieved a significant breakthrough in the development of a hybrid silicon photocatalyst. This innovative catalyst utilizes solar power to produce hydrogen and high-value compounds efficiently, marking a major step forward in green hydrogen production technology.

The newly developed photocatalyst is both non-toxic and eco-friendly, addressing the limitations associated with previous catalysts that were not sunlight-responsive or posed toxicity concerns. Silicon-based photocatalysts demonstrate excellent light absorption properties, making them highly efficient in utilizing solar energy. Moreover, these non-toxic materials do not emit harmful chemicals during their production process.

Figure 1. Schematic illustration of the synthesis and application of SiF/Ni-NGQDs for efficient biomass reforming and hydrogen production under solar irradiation and mild conditions.

Previous research faced challenges in achieving continuous production of hydrogen alongside high-value compounds due to a lack of suitable catalysts. Toxic catalysts used under strong base conditions often led to environmental pollution issues. Additionally, as oxide layers formed on traditional silicon photocatalysts during reactions, it negatively impacted hydrogen production efficiency over time.

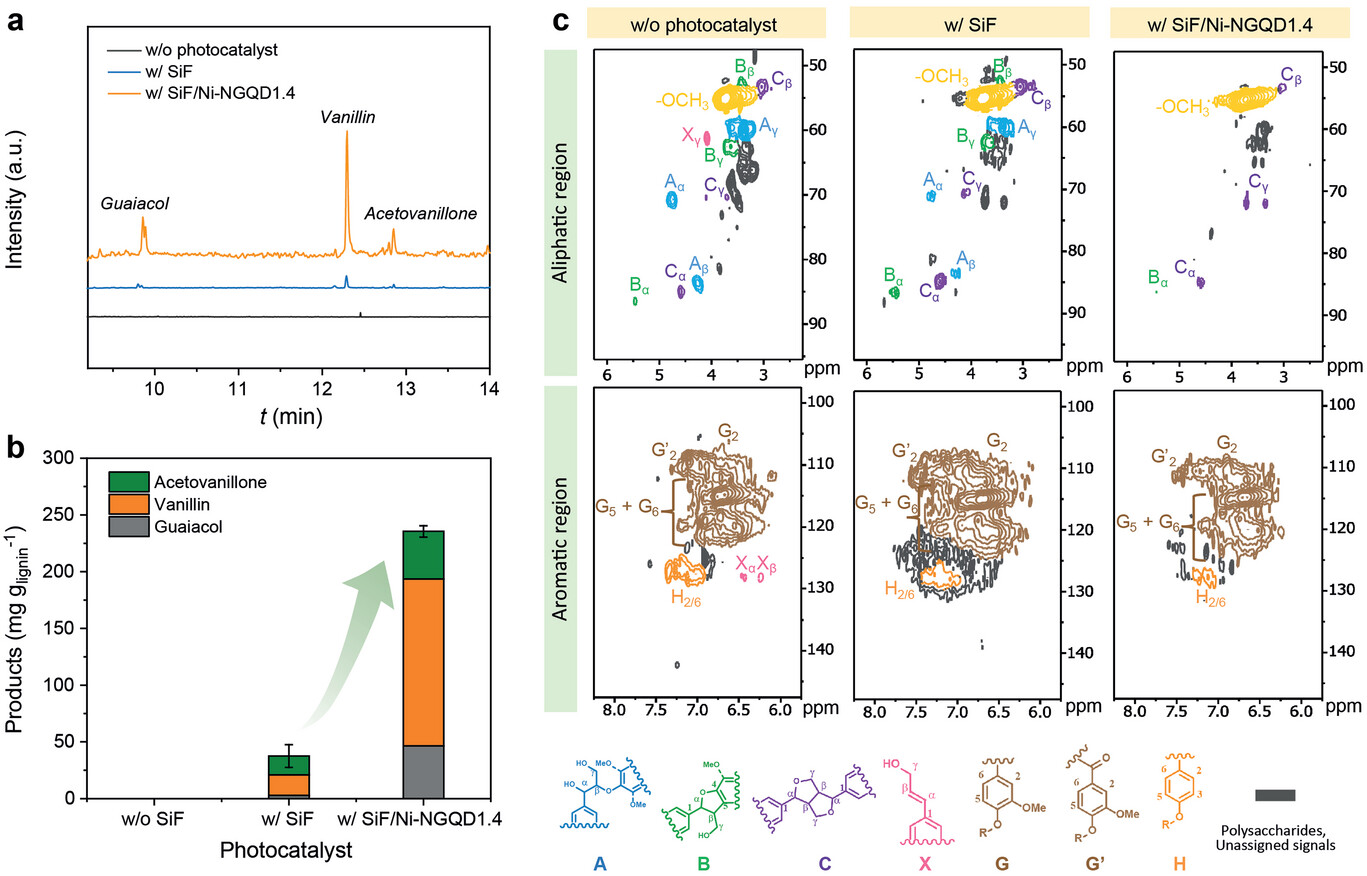

To overcome these obstacles, the research team developed a hybrid silicon photocatalyst by uniformly coating nickel-doped graphene quantum dots onto the surface of 2 to 3 nm thick silicon flakes. The modified surface enabled significantly higher hydrogen production efficiency compared to conventional silicon photocatalysts—achieving an impressive rate of 14.2 mmol gcat−1 h−1—a substantial improvement equating to approximately 28 times higher performance.

Furthermore, through oxidation reactions using biomass instead of water—an organic substance derived from biological sources—the hybrid silicon photocatalyst demonstrated its capability for producing high-value compounds alongside hydrogen production. The catalyst also maintained 98% of its original form, ensuring long-term stability.

Figure 2. Photo-reforming of lignin depolymerization using SiF/Ni-NGQD photocatalysts. a) GC-MS spectra for the identification and quantification of the lignin byproducts after the irradiation of the simulated sunlight for 6 h. b) Comparison of the vanillin yield under various conditions. c) 2D NMR spectra of the residual lignin after the simulated solar irradiation for 6 h with and without photocatalysts.

Professor Ryu stated, “Previous research on hydrogen production has been limited to photocatalysts that absorb ultraviolet rays or involve toxic catalysts. Our non-toxic and cost-effective silicon photocatalyst is a significant advancement as it enables high-efficiency hydrogen production through superior solar absorption.”

Professor Park added, “The surface modification technique utilizing nickel-doped graphene quantum dots can be applied not only to silicon photocatalysts but also to various other types of photocatalysts, opening up new possibilities in energy applications.”

The study has been jointly participated by Yuri Choi (Research Assistant Professor, School of Energy and Chemical Engineering, UNIST) and Sungho Choi (Combined MS/Ph.D. Program of Advanced Materials Science, POSTECH). The findings of this study were published in Advanced Materials on July 27, 2023. This study has been supported by the grants through the National Research Foundation of Korea (NRF) funded by the Ministry of Science and ICT of Korea, as well as the Basic Science Research Program through the NRF funded by the Ministry of Education of Korea.

Journal Reference

Yuri Choi, Sungho Choi, Inhui Lee, Trang Vu Thien Nguyen, et al., “Solar Biomass Reforming and Hydrogen Production with Earth-Abundant Si-Based Photocatalysts,” Advanced Materials, (2023).