A groundbreaking technology enabling the fabrication of intricate three-dimensional (3D) quantum dot (QD)-based structures at room temperature has been unveiled.

Led by Professor Im Doo Jung from the Department of Mechanical Engineering at UNIST, a recent study has introduced a cutting-edge one-stop perovskite quantum dot (PQD) additive manufacturing technology. This innovative approach eliminates the need for heat treatment, allowing for the creation of complex 3D shapes with exceptional precision, including iconic landmarks like the Eiffel Tower.

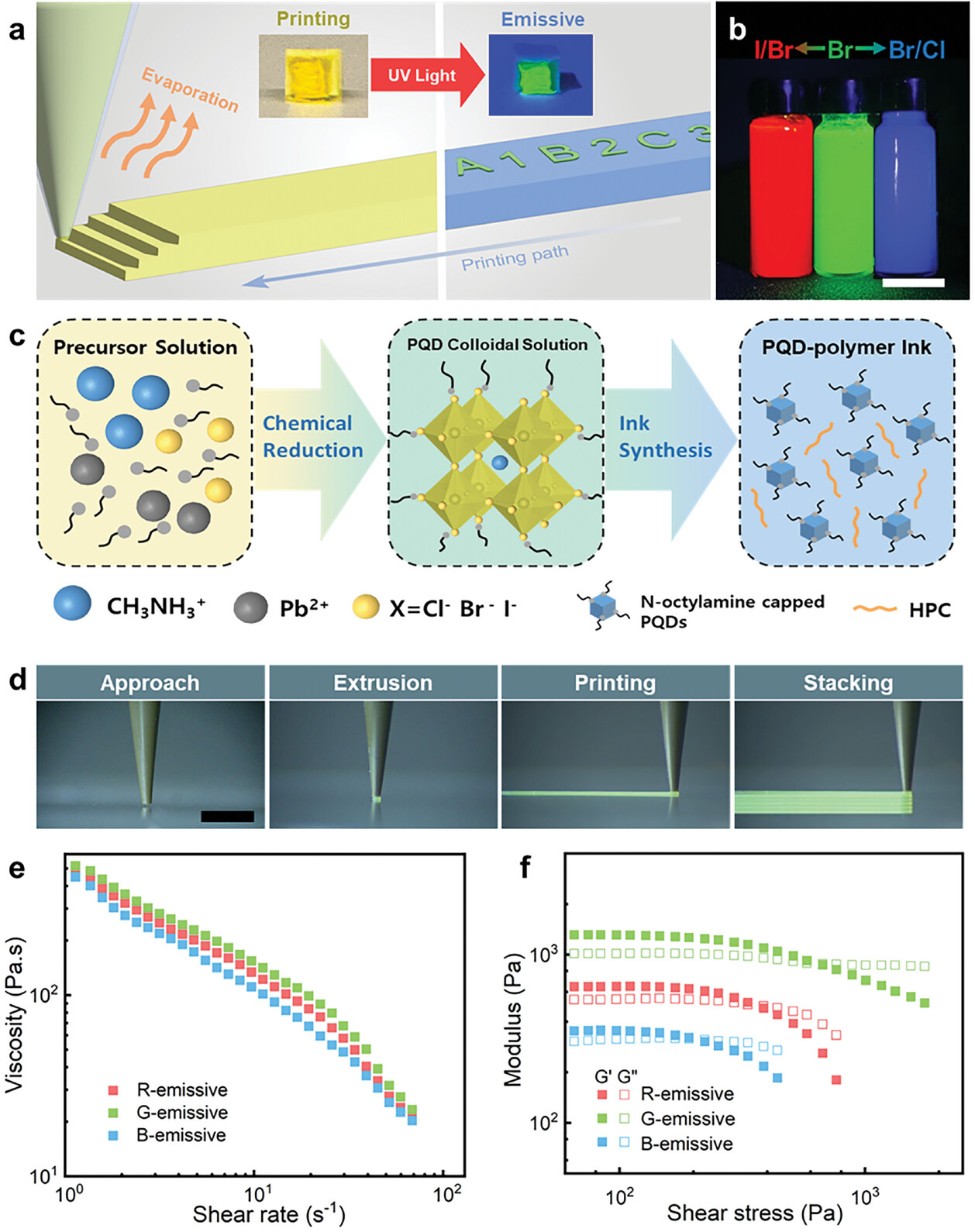

Figure 1. a) Schematic of the direct-ink writing (DIW) approach of luminescent PQD–polymer architectures. Hydroxypropyl cellulose (HPC) polymer was dissolved in DCM to prepare a 3D printable ink. b) Optical image of the inks as visible in 385-nm ultraviolet (UV) light. PQD–polymer inks display red (R), green (G), and blue (B) emissive colors, corresponding to the halide ratios of CH3NH3PbBr1.5I1.5, CH3NH3PbBr3, and CH3NH3PbBr1.5Cl1.5. The scale bar is 5 mm. c) Schematic of the synthesis of luminescent PQDs as a colloidal dispersion solution in toluene, including the synthesis of PQD-polymer ink with HPC. d) Optical images of the DIW process show continuous deposition of a line pattern on the glass substrate. The scale bar is 1 mm. e) Rheological property depicts a decrease in the viscosity of the ink as the shear rate increases (shear-thinning behavior). f) Solid-like inks are shifted to a liquid-like fluid as a rheological function of the shear stress.

Traditionally, shaping QD materials in 3D required prolonged heat exposure, leading to property degradation and shape deformation. However, the newly developed PQD materials exhibit remarkable luminous efficiency and color versatility, offering a game-changing solution for advanced encryption and anti-counterfeiting applications.

By meticulously optimizing key printing variables and utilizing hydroxypropyl cellulose (HPC) polymer and dichloromethane (DCM) as a volatile solvent, the research team achieved stable extrusion of luminescent PQD inks at room temperature. This innovative 3D printing method enables the creation of diverse structures emitting light in red, green, and blue (RGB) colors based on the primary light colors.

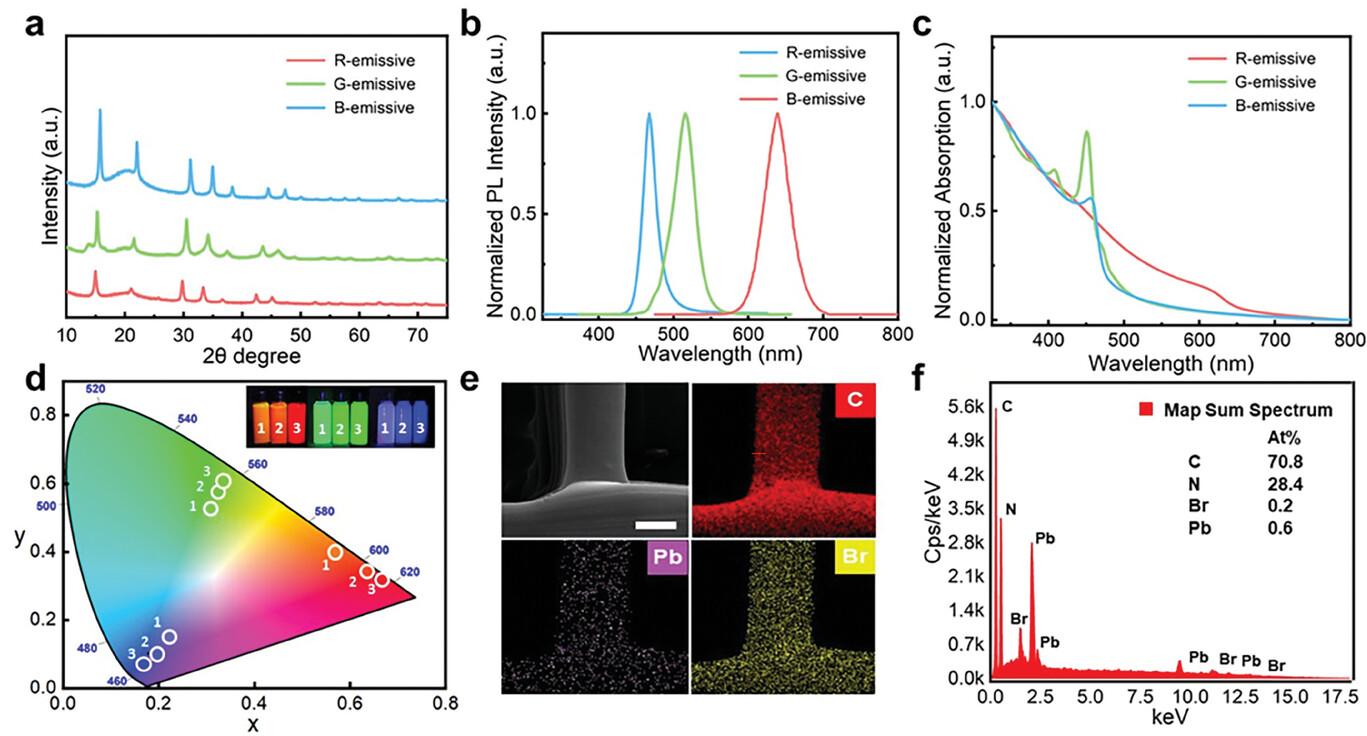

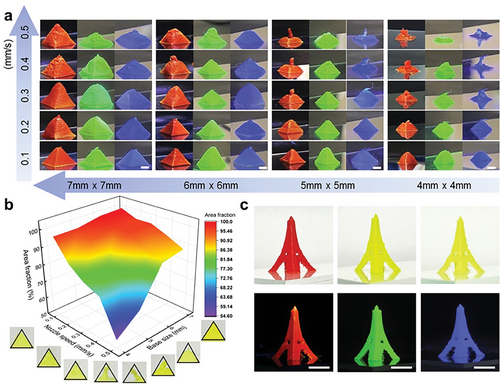

Figure 2. Characteristics of R, G, and B-emissive PQD–HPC architectures.

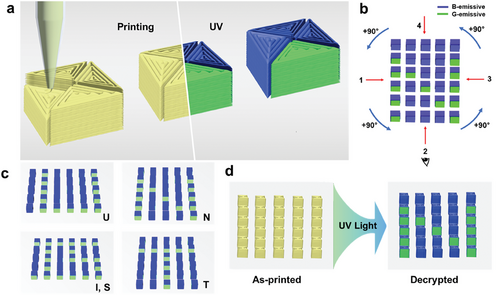

The study introduces a sophisticated anti-counterfeiting and encryption system utilizing 3D-printed geometric shapes that leverage the unique light emission properties of PQDs. Demonstrating the potential for enhanced security features in modern printed electronic devices, a 6 x 5 cube architecture array was designed using G- and B-emissive PQD-HPCs for encryption, displaying alphabetic letters (U, N, IS, and T) at 90° intervals.

Figure 3. Optical images depict the 3D printability of an R, G-, and B-emissive pyramid architecture for the layer-by-layer method using repetitive stacking via the micronozzle.

Lead author Hongryung Jean emphasized the significance of this breakthrough, stating, “Our streamlined QD 3D printing process enables stable manufacturing at room temperature, promising advancements in information encryption systems and optoelectronic printing technologies.”

Professor Jung highlighted the impact of this research on expanding QD-based applications and enhancing anti-forgery solutions, stating, “This advancement preserves the photoluminescence properties of PQDs without the need for heat treatments, driving innovation in optoelectronic and energy applications.”

Figure 4. a) Illustration of printed bicolor anti-counterfeiting cubic architectures comprising triangular units. b) Schematic design of a 6 × 5 3D array consisting of G- or B-emissive PQD–HPC on individual cube faces. The array sides encrypt information, with the denoting at 90° counterclockwise intervals. c) Design of a collective encryption of alphabets (U, N, I, S, T) as viewed from the top. The decryption in an inclined view of each array side, denoting U, N, IS, and T letters. d) Illustration of 3D printed 6 × 5 array cubic architectures under daylight and 385-nm UV light. The as-printed array decrypts information under UV light.

The research findings have been published in the March 2024 edition of Advanced Functional Materials, a top-tier academic journal in the field. Supported by the National Research Foundation (NRF) of Korea and other key institutions, this research sets a new standard for encryption technology and anti-counterfeiting measures in the digital age.

Journal Reference

Hongryung Jeon, Muhammad Wajahat, Seobin Park, et al., “3D Printing of Luminescent Perovskite Quantum Dot–Polymer Architectures,” Adv. Funct. Mater., (2024).