A groundbreaking advancement in neutron shielding, a critical aspect of radiation protection, has been achieved. This breakthrough is poised to revolutionize the neutron shielding industry by offering a cost-effective solution applicable to a wide range of materials surfaces.

A research team, led by Professor Soon-Yong Kwon in the Graduate School of Semiconductors Materials and Devices Engineering and the Department of Materials Science and Engineering at UNIST has successfully developed a neutron shielding film capable of blocking neutrons present in radiation. This innovative shield is not only available in large areas but also lightweight and flexible.

“The developed Maxine-Boron carbide composite shielding film is several tens of micrometers thick, over 1,000 times thinner than conventional commercial materials,” noted Professor Kwon. “It can be effortlessly applied to various surfaces, resembling the act of painting.”

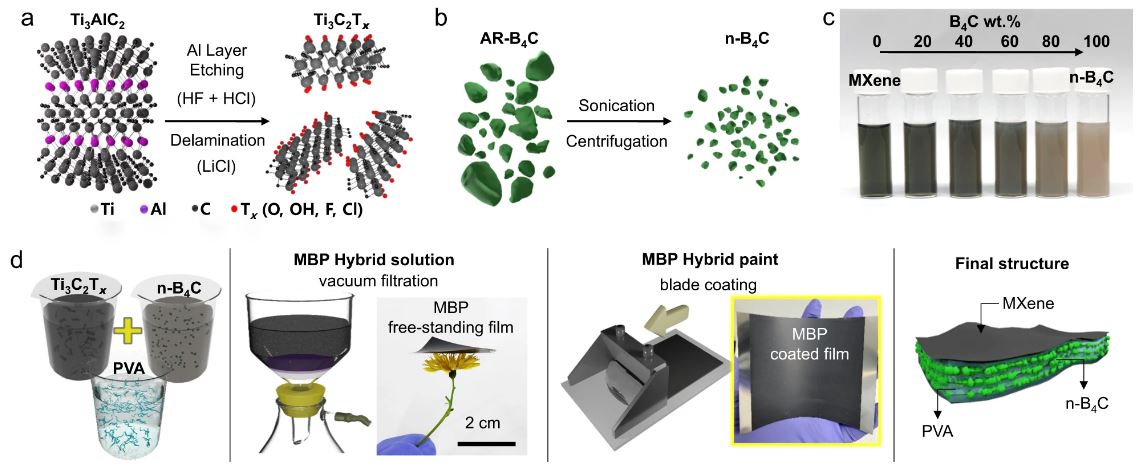

Figure 1. Solution-based process for MXene composite films with incorporated B4C particles. (a) Synthesis of the Ti3C2Tx MXene through the mixed etchant (HF + HCl) and inorganic intercalant (LiCl). (b) Size selection from the as-received B4C (AR-B4C) to nano-sized B4C (n-B4C). (c) Stable and homogeneous dispersion of MXene/n-B4C hybrid colloid solutions with various B4C concentrations. (d) Preparation of the Ti3C2Tx/n-B4C/PVA (MBP) hybrid solution and its film fabrication using vacuum-assisted filtration and blade-coating methods.

Neutrons, which are integral to nuclear power generation, medical devices, and aerospace industries, possess inherent dangers when leaked. They can trigger unexpected phenomena in electronic devices or living organisms through interactions with other atoms.

The research team directly synthesized MXenes, a two-dimensional nanomaterial and the parent MAX phases. Additionally, they devised a technique to divide boron carbide into small pieces capable of absorbing neutrons and incorporated them between the maxillary layers. Based on this breakthrough, a large-area, flexible, and lightweight film was developed. Furthermore, a painting technique was devised to apply the developed mixture to diverse surfaces.

Co-first author Ju Hyoung Han, a researcher in the Department of Materials Science and Engineering at UNIST, stated, “By controlling the properties of maxine and boron carbide, we improved the stability of the mixture solution of the two materials. We successfully created a light and flexible shield with a stabilized maxine-boron mixture, which can be applied like paint on various objects’ surfaces, as demonstrated through experiments.”

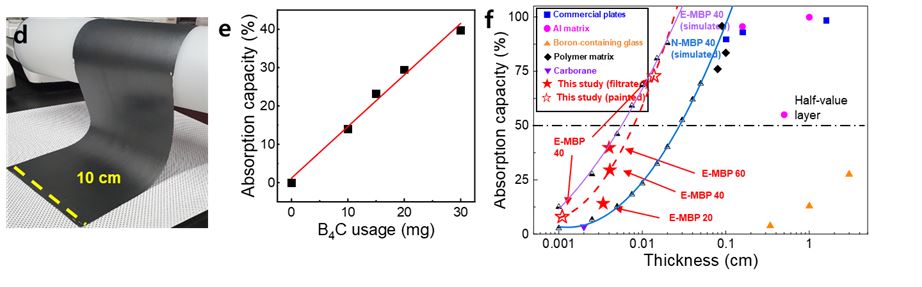

Figure 2. Neutron-shielding performances of MBP hybrid films. (d) Photograph of the painted MBP hybrid film on the nylon membrane with a large area of 10 × 30 cm2. (e) Neutron absorption capacity of MBP hybrid films with different B4C usages. (f) Neutron absorption capacity vs. thickness of boron-based composites.

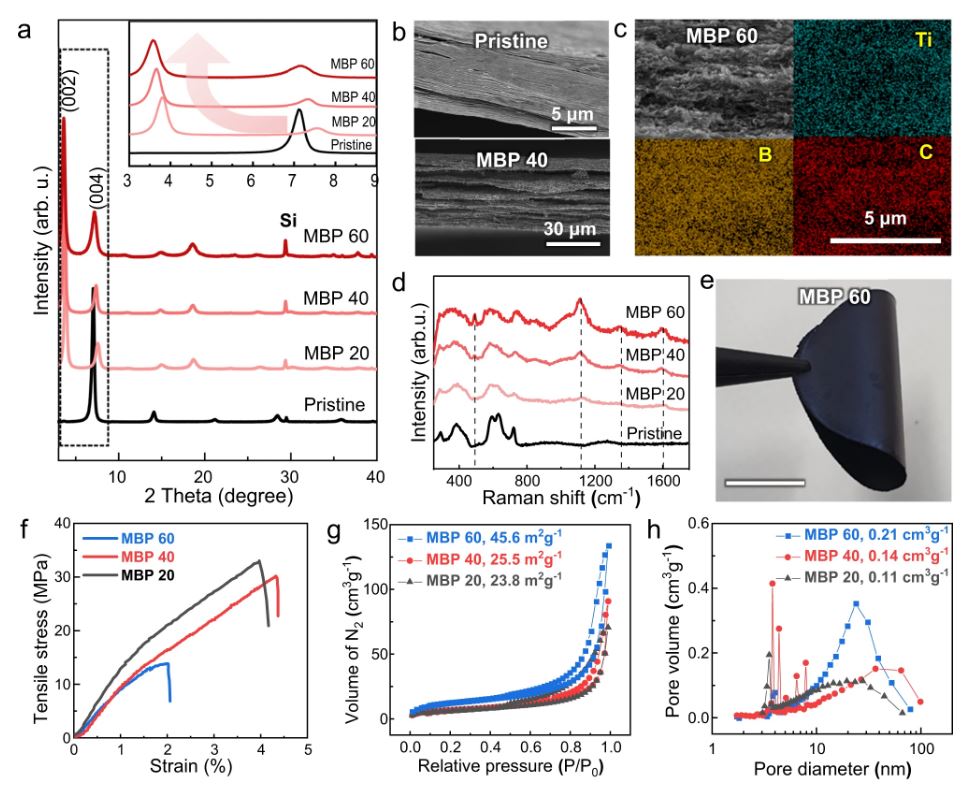

The developed neutron shield possesses a dense structure with minimal bubble holes, measuring only several tens of nanometers. Consequently, it exhibits excellent mechanical properties compared to previously used polymer-based composites. Since additional processes such as heat treatment are unnecessary, a pure mixed structure without impurities can be manufactured.

Co-first author Si-Hyun, Seok, a researcher in the Department of Materials Science and Engineering at UNIST, commented, “Even after over 20,000 bending tests, the nylon composite coated with the shielding film maintained its circular shape up to 98%. It demonstrated an exceptional neutron shielding rate (40% when using 30mg) even with milligrams of boron carbide, showcasing its superiority.”

Figure 3. Structural characterization of MXene/B4C/PVA (MBP) hybrid films. (a) XRD comparison of MBP hybrid films. An enlarged pattern in the range of 2°–9° is shown in the inset. (b) Cross-sectional SEM images of the pristine Ti3C2Tx and MBP 40 hybrid film. (c) Cross-sectional SEM image and corresponding EDS mapping results of MBP 60. (d) Raman spectra of the MBP hybrid films. The dashed lines represent characteristic peaks of B4C. (e) Photograph of the MBP 60 freestanding film showing its good flexibility (scale bar, 1 cm). (f) Tensile strain–stress curves of the MBP hybrid films. (g) N2 BET analysis of the MBP hybrid films. (h) BJH pore size distributions of the MBP hybrid films. Calculated surface areas and pore volumes are included in (g) and (h), respectively.

Professor Kwon added, “The newly developed composite manufacturing technology is practical and requires neither complex equipment nor processes. It enables the implementation of a neutron shielding coating film with the desired thickness and area. This study will expand the possibilities of Maxine material coating technology and demonstrate its application in various fields.”

The findings of this study have been published in the online version of Nature Communications on October 31, 2023. It has received support from the Ministry of Science and ICT (MSIT) and the National Research Foundation (NRF) of Korea.

Journal Reference

Ju-Hyoung Han, Shi-Hyun Seok, Young Ho Jin, et al., “Robust 2D layered MXene matrix–boron carbide hybrid films for neutron radiation shielding,” Nat. Commun., (2023).