Gold, a precious metal, is arguably the most widely used metal across jewelry and coinage due to its physical properties that are unique to the world of metals. Not only is it a good conductor of heat and electricity, it is unaffected by air and most reagents. It is also used in a wide range of industrial, scientific, and medical applications. For example, it has been used as the template for molecular self-assembly, the supporting material for two-dimensional materials growth, and especially for the synthesis of carbon nanoribbons. More than half a century ago, researchers unveiled the fancy textures on gold surfaces at the nanoscale. Efforts for a better understanding of the surface structures on the atomic scale have been continually paid for from then on.

Au(111) surface, the most stable gold surface, has a periodic herringbone texture on it that can be observed by sophisticated microscopes (See Figure 1A). A long-term puzzle is why this strange herringbone forms on this gold surface. Extensive studies have been performed for decades but a thorough description of structure details is still missing and thus the underlying mechanism has never been properly understood. The difficulties in this issue lie in the fact that even though the size of the texture is at the nanoscale, its periodic unit still contains more than 100,000 atoms. To quantitatively study this system, one needs a very efficient and also very accurate computational method. In traditional approaches, however, these two requirements cannot be satisfied simultaneously.

Recently, Distinguished Professor Feng Ding (Department of Materials Science and Engineering) and his colleagues from the Center for Multidimensional Carbon Materials (CMCM), within the Institute for Basic Science (IBS) at UNIST, utilized the state-of-the-art neural network method to train a gold force field from an accurate but slow computational method.

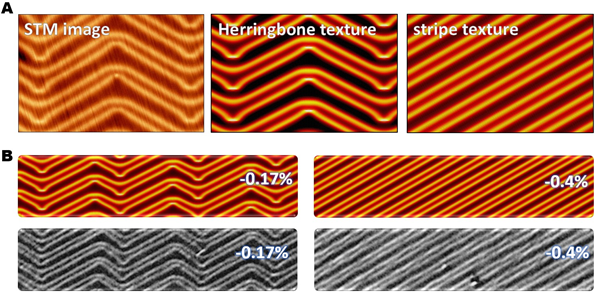

Due to the powerful learning ability of neural networks, this new force field acquires almost the same accuracy, and more importantly, it is many orders of magnitude faster than the original method. Using this force field, the authors successfully simulated the experimentally observed herringbone texture on Au(111) surface and revealed that there is non-negligible deformation underneath the surface. This deformation is critical for the formation of the herringbone texture because it allows an effective relaxation of the rearranged surface atoms. If the deformation is suppressed (take a thin model for instance), the texture will become stripes, as shown in Figure 1(A).

Figure 1. (A) From left to right are the experimentally observed herringbone texture, and the simulated herringbone and stripe textures on thick and thin models respectively. (B) Effect of strain on textures. The simulated textures are shown in color and the observed textures are shown in grey.

Meanwhile, the authors also verified that the herringbone texture is sensitive to applied strains. On a strain-free surface, the herringbone texture is mirror-symmetric. However, if a slight strain is introduced, the texture becomes tilted (Figure 2B). Above a critical strain, it thoroughly transforms into a stripe texture.

“This important work extends the application of the machine learning method in material science and opens a new avenue to study complex surface systems,” noted the research team.

Led by Distinguished Professor Feng Ding, this study was first authored by Dr. Pai Li. The findings of this research have been published in the October 2022 issue of the prestigious Science Advances.

Journal Reference

Pai Li, Feng Ding., “Origin of the herringbone reconstruction of Au(111) surface at the atomic scale” Science Advances, (2022).