A team of researchers, led by Professor Sung-Yeon Jang at UNIST’s School of Energy and Chemical Engineering has achieved a significant breakthrough with the development of a groundbreaking stretchable and self-healing polymer. This innovative material exhibits remarkably high ionic thermoelectric (iTE) properties, boasting an impressive ionic figure-of-merit of 12.3 at 70% relative humidity (RH), making it highly efficient for energy conversion. The findings hold immense potential for wearable technology as it can be charged solely through the body’s heat without relying on traditional batteries.

In collaboration with Professor Ju-Won Jeon from Kookmin University, the research team has successfully developed an exceptional high-performance intelligent thermoelectric (iTE) material capable of self-healing under conditions involving both high electric and mechanical stress.

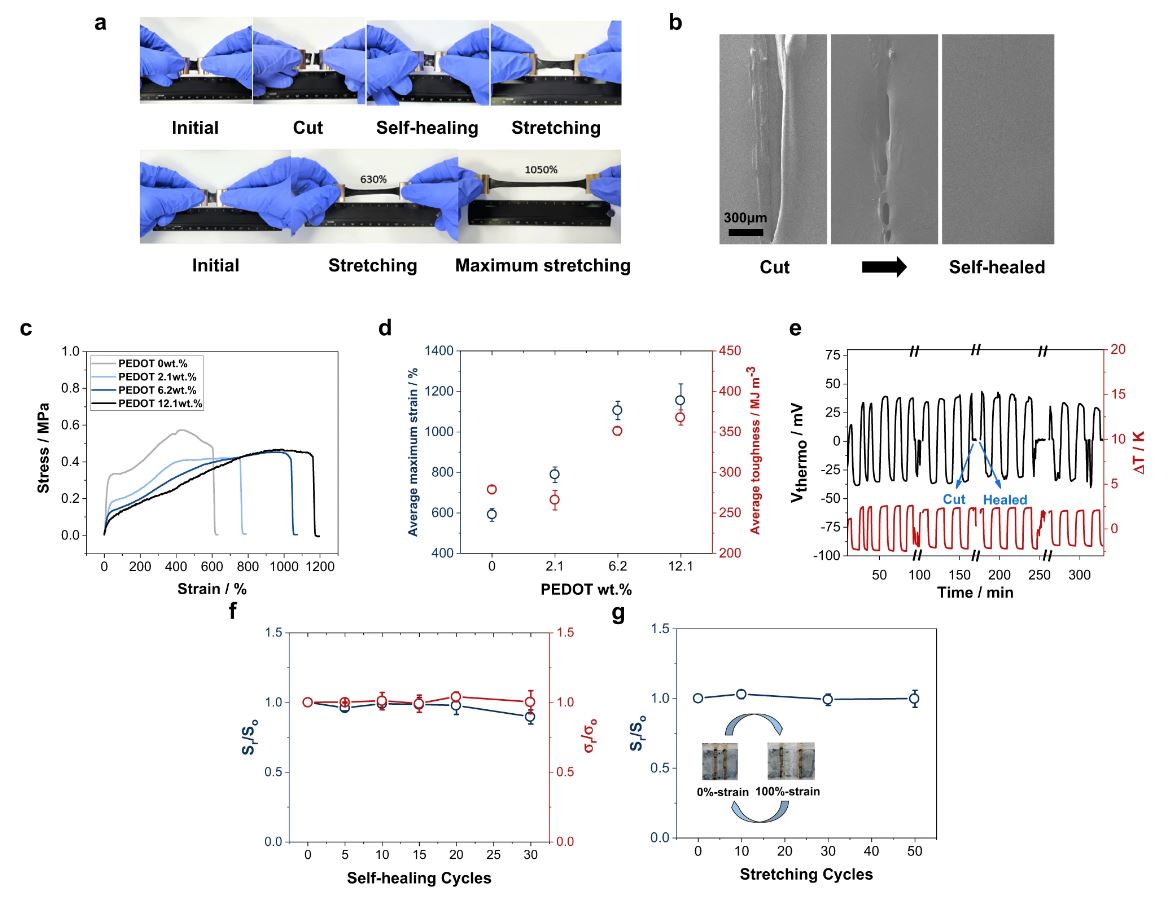

Thermoelectric materials are environmentally friendly energy sources that convert thermal energy into electricity. By employing self-healable TE materials that restore themselves even when torn or cut due to strong interactions between molecules within the material, the research team achieved outstanding results in maintaining mechanical properties and electrical performance. Additionally, they conducted comprehensive analyses optimizing various factors affecting iTE properties—factors often overlooked in previous studies. Through this approach, they developed a material exhibiting ultra-high-efficiency thermoelectric conversion performance along with excellent mechanical properties and self-healing capabilities.

Figure 1. Mechanical properties of PEDOT:PAAMPSA:PA films. (a) Photos of the self-healing and stretching of a PEDOT:PAAMPSA:PA (6.2wt.% PEDOT) free-standing film. (b) SEM images of each self-healing stage of a PEDOT:PAAMPSA:PA (6.2wt.% PEDOT) thin film on a glass substrate at 70% RH. Scale bar indicates 300 µm. (c) Stress-strain curves of PAAMPSA:PA and PEDOT:PAAMPSA:PA free-standing films with different PEDOT/PAAMPSA ratios at 60% RH. The thickness of the free-standing films is 0.8 mm. (d) Average maximum strain and toughness of PAAMPSA:PA and PEDOT:PAAMPSA:PA free-standing films with different PEDOT/PAAMPSA ratios at 60% RH. (e) Thermovoltage profile of a PEDOT:PAAMPSA:PA (6.2 wt.% PEDOT) thin film during a real-time self-healing at 70% RH. (f) Stability of Si and σi during repeated self-healing cycles at 70% RH. (g) Stability of Si during repeated stretching cycles (strain of 100%) at 70% RH. The subscript “o” indicates the original values before mechanical stresses and “r” indicates the recovered values after mechanical stresses. All values in (d), (f), and (g) are averaged from three samples each.

With electronic devices commonly worn on the human body—such as Bluetooth headphones and smartwatches—becoming increasingly prevalent, there is growing demand for independent power sources free from limitations associated with liquid electrolyte-based lithium-ion (Li-ion) batteries—including leakage concerns—and external power charging requirements. Ionic polymer TE materials offer great potential due to their unique flexibility and ability to generate electricity from surrounding thermal energy.

However, current TE materials have lower thermal energy conversion performance compared to existing lithium-ion batteries, necessitating further improvements for commercialization. Additionally, there is a lack of systematic scientific analysis aimed at enhancing their performance.

The research team achieved optimized thermal energy conversion performance by conducting a thermodynamic analysis of the ionic thermoelectric effect within the material—for the first time in the world. The resulting ionic thermoelectric performance index reached an impressive 12.3—more than 70% higher than previous records. In addition to its remarkable self-healing capabilities, the material demonstrates excellent physical properties—capable of extending over ten times its original length—while maintaining both mechanical and electrical integrity without any loss in performance even after more than 50 repeated durability experiments.

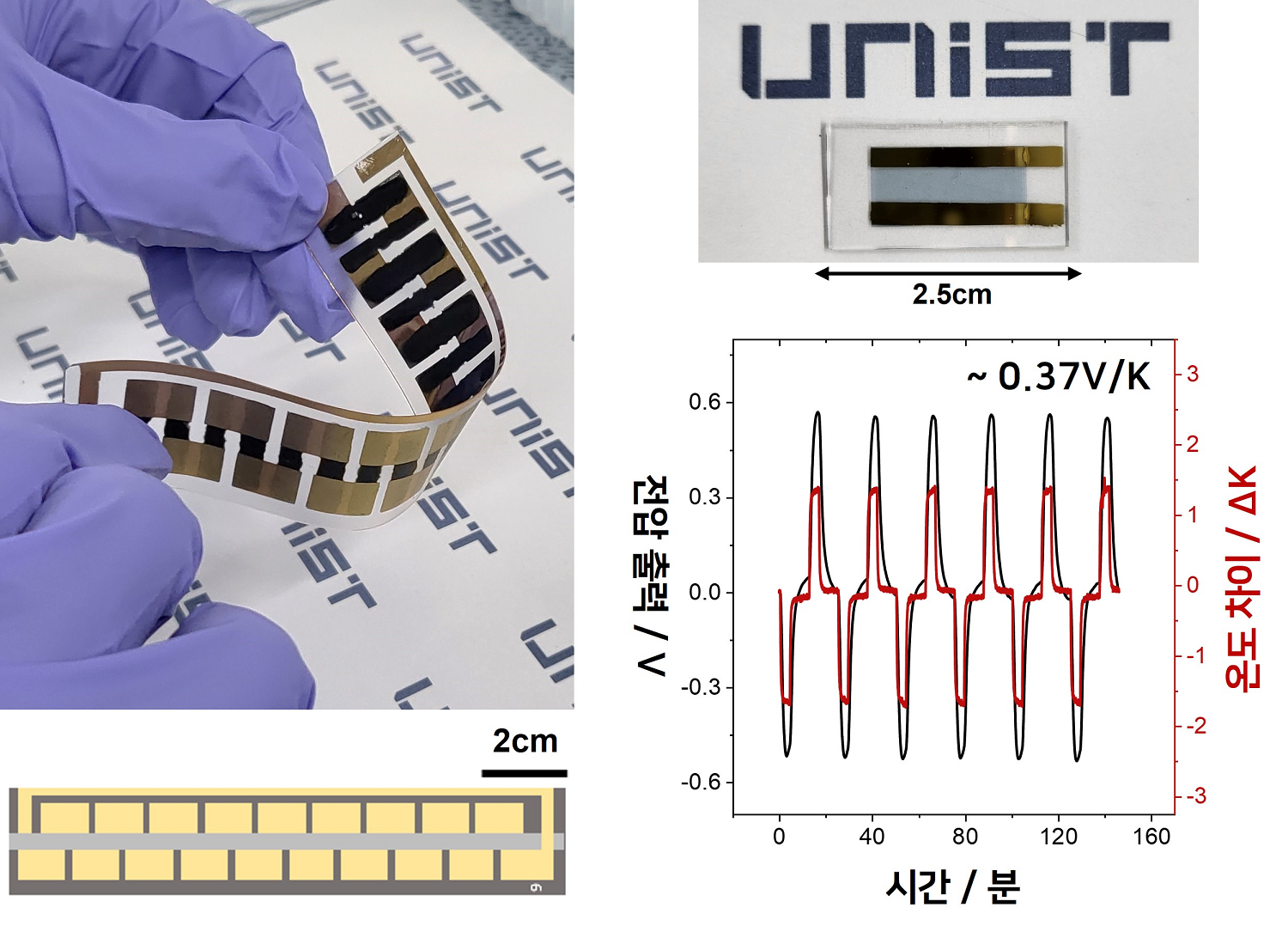

Figure 2. Photos of ITEC module (left) and ITESC device (upper right).

Figure 2. Photos of ITEC module (left) and ITESC device (upper right).

To showcase practical application potential, the researchers manufactured an ionic thermoelectric supercapacitor (ITESC) device, using their newly-developed materials and even created modules that amplify output by connecting multiple devices in series. These modules demonstrated remarkably high voltage output (0.37V/K), proving that the developed thermoelectric material generates sufficient voltage to power multiple electronic devices in real-life scenarios. This implies that with just a temperature difference as small as 10 degrees Celsius from room temperature, it can produce similar voltage outputs compared to conventional lithium-ion batteries (approximately 3.7V).

“Our research opens up exciting possibilities for enhancing thermal energy conversion efficiency,” stated Professor Jang. “This study encompasses all essential aspects—from material design considerations encompassing mechanical and electrical properties to practical demonstrations of commercialization through modules.”

The study findings have been published in Nature Communications on June 5, 2023. This work has received support from the National Research Foundation (NRF) of Korea, funded by the Ministry of Science and ICT (MSIT).

Journal Reference

Dong-Hu Kim, Zico Alaia Akbar, Yoga Trianzar Malik, et al., “Self-healable polymer complex with a giant ionic thermoelectric effect,” Nat. Comm., (2023).