The rapid advancements in flexible electronic technology have led to the emergence of innovative devices such as foldable displays, wearables, e-skin, and medical devices. These breakthroughs have created a growing demand for flexible adhesives that can quickly recover their shape while effectively connecting various components in these devices. However, conventional pressure-sensitive adhesives (PSAs) often face challenges in achieving a balance between recovery capabilities and adhesive strength. In an extraordinary study conducted at UNIST, researchers have successfully synthesized new types of urethane-based crosslinkers that address this critical challenge.

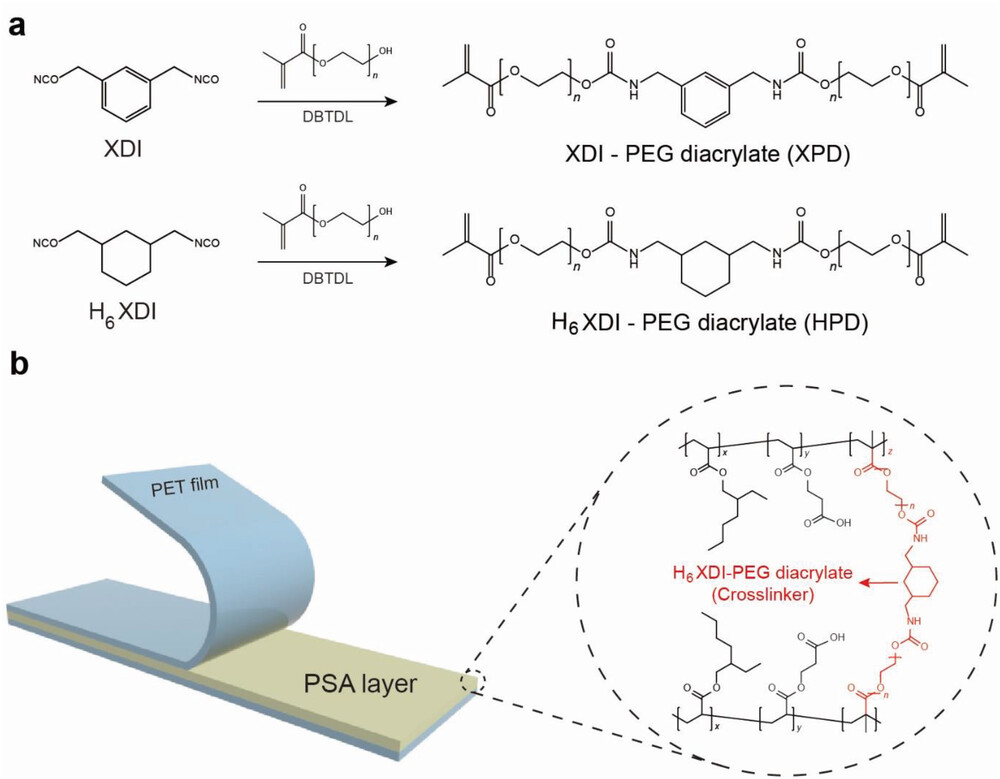

Led by Professor Dong Woog Lee from the School of Energy and Chemical Engineering at UNIST, the research team developed novel crosslinkers utilizing m-xylylene diisocyanate (XDI) or 1,3-bis(isocyanatomethyl)cyclohexane (H6XDI) as hard segments along with poly(ethylene glycol) (PEG) groups serving as soft segments. By incorporating these newly synthesized materials into pressure-sensitive adhesives, they achieved significantly improved recoverability compared to traditional methods.

Figure 1. Synthesis of a) XDI-PEG diacrylate (XPD) and H6XDI-PEG diacrylate (HPD). b) Molecular structure of PSA crosslinked with H6XDI-PEG diacrylate (HPD).

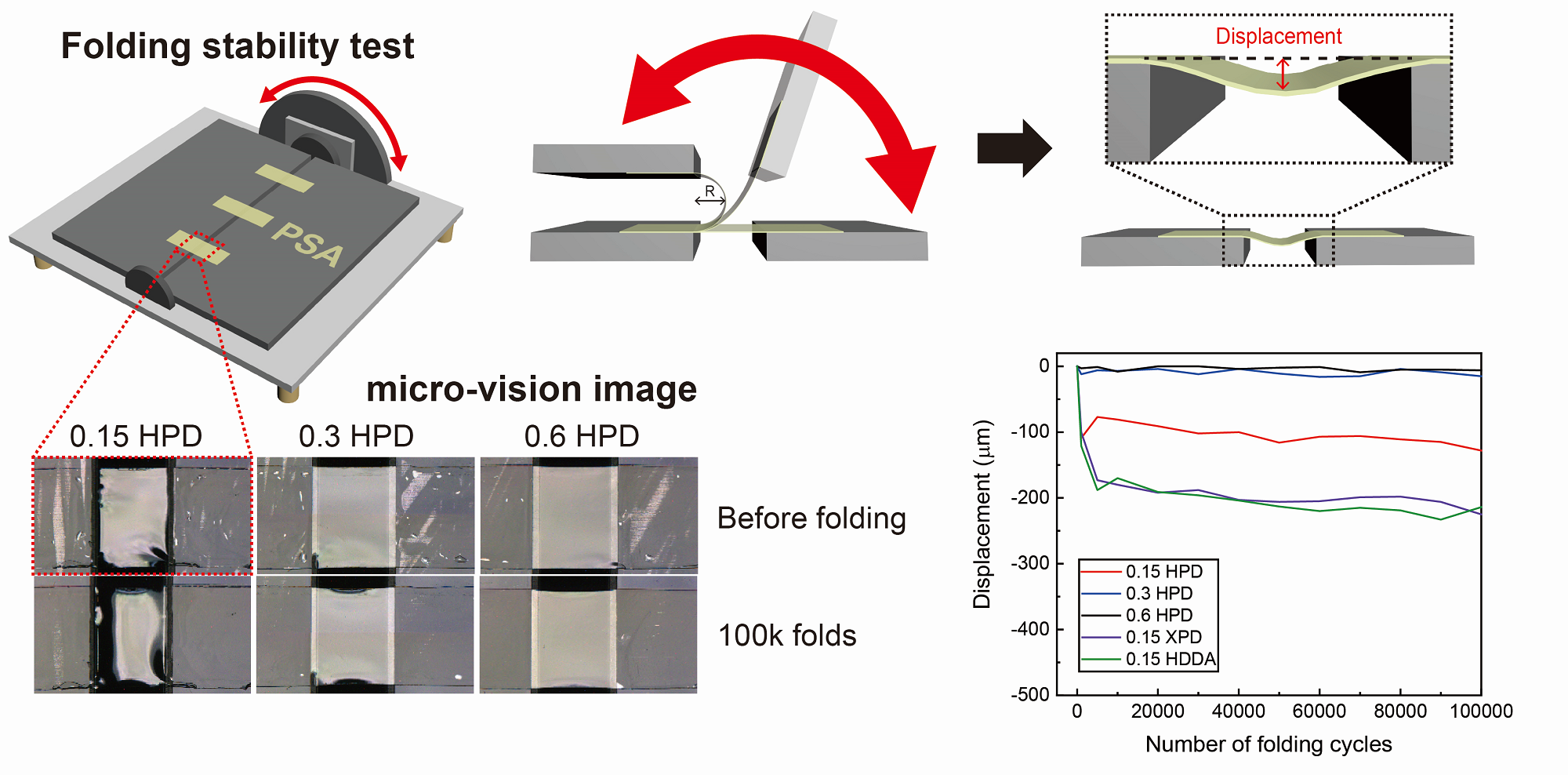

The PSA formulated with H6XDI-PEG diacrylate (HPD) demonstrated exceptional recovery properties while maintaining high adhesion strength (~25.5 N 25 mm−1). Through extensive folding tests totaling 100k folds and multi-directional stretching tests spanning 10k cycles, the PSA crosslinked with HPD exhibited remarkable stability under repeated deformation—showcasing its potential for applications requiring both flexibility and recoverability.

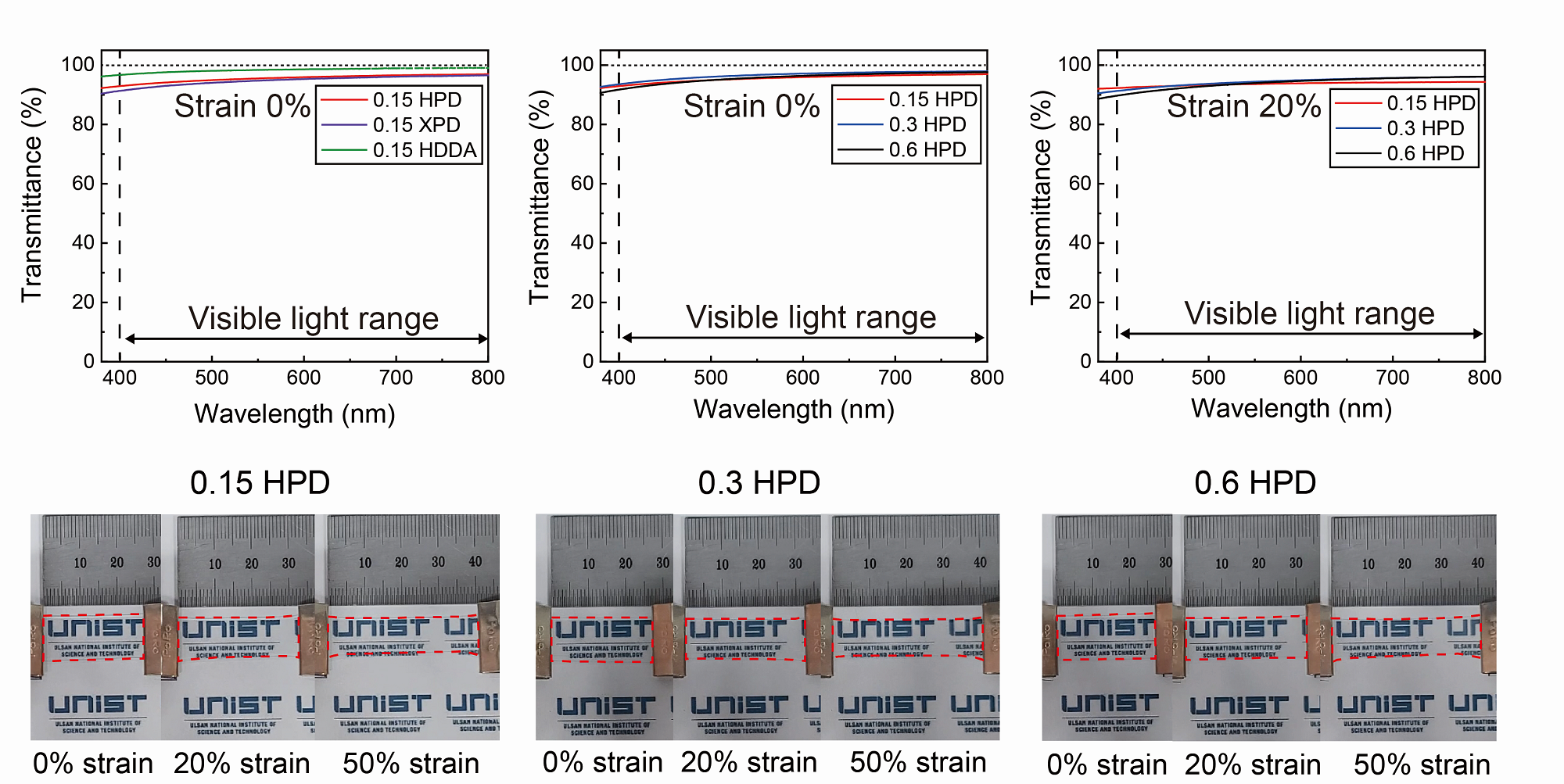

Furthermore, even after subjecting the adhesive to strains up to 20%, it displayed high optical transmittance (>90%), making it suitable for fields such as foldable displays that demand not only flexibility but also optical clarity.

Figure 2. Stretching and folding test of PSAs. A schematic illustration of the folding stability test operating procedure and the displacement change of the elongated PSA after folding. Bottom left is the micro-vision image of 0.15 HPD, 0.3 HPD, and 0.6 HPD before and after 100k folds. Bottom right is a graph illustrating the displacement change of each PSA during 100k folds.

Figure 2. Stretching and folding test of PSAs. A schematic illustration of the folding stability test operating procedure and the displacement change of the elongated PSA after folding. Bottom left is the micro-vision image of 0.15 HPD, 0.3 HPD, and 0.6 HPD before and after 100k folds. Bottom right is a graph illustrating the displacement change of each PSA during 100k folds.

“This breakthrough in adhesive technology offers promising possibilities for electronic products that require both high flexibility and rapid recovery characteristics,” said Professor Lee. “Our research addresses the long-standing challenge of balancing adhesion strength and resilience, opening up new avenues for the development of flexible electronic devices.”

Figure 3. (Left) The transmittance of PSAs crosslinked with HPD, XPD, and HDDA. The transmittance of PSAs. (Center) as a function of HPD content and c) applied strain. (Right) The optical images of 0.15 HPD, 0.3 HPD, and 0.6 HPD under different strains.

Hyunok Park, a researcher involved in the study, emphasized the significance of this research by stating, “The introduction of this new crosslinking structure has led to an adhesive with exceptional adhesion and recovery properties. We believe it will drive future advancements in adhesive research while contributing to further developments in flexible electronics.”

The study findings have been published ahead of their official publication in the online version of Advanced Functional Materials on July 12, 2023. This work was supported through the 2023 Research Fund at UNIST and received additional support from organizations including the National Research Foundation (NRF) of Korea, Defense Acquisition Program Administration and Ministry of Trade.

Journal Reference

Hyunok Park, Daegyun Lim, Geonwoo Lee, et al., “Tailoring Pressure Sensitive Adhesives with H6XDI-PEG Diacrylate for Strong Adhesive Strength and Rapid Strain Recovery,” Adv. Funct. Mater., (2023).