Foldable batteries have attracted much attention, as many companies around the world, including Samsung Electronics, appear to be one step closer to producing much-rumored foldable smartphones a reality.

A new study, affiliated with UNIST has introduced a high impact-resistant foldable Lithium-ion batteries that can withstand shocks that would destroy most standard batteries.

This breakthrough has been led by Professor Hyun-Kon Song and Professor Soojin Park in the School of Energy and Chemical Engineering at UNIST. Their work has been also selected to appear on the front cover of December 2017 issue of Advanced Materials.

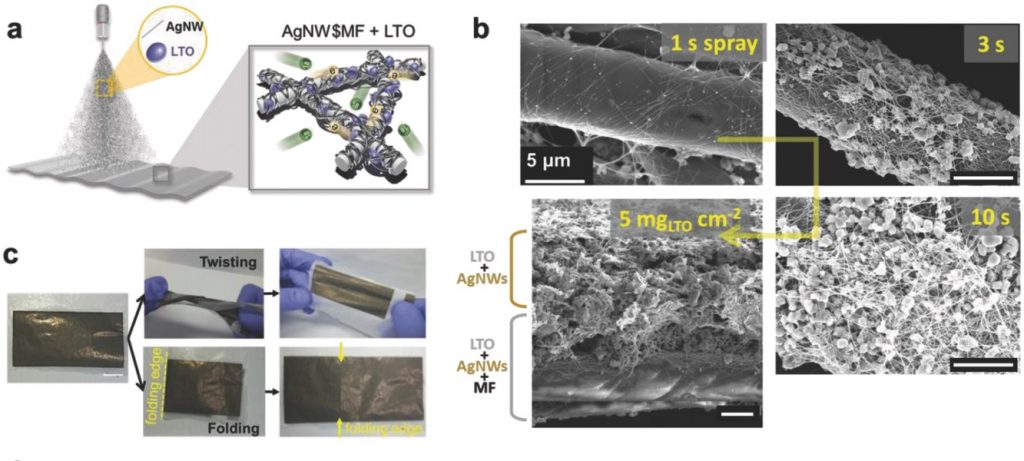

The new electrode architecture, the research team has introduced in the study, showed ultraflexibility that tolerate folding, bending, and crumpling. According to the research team, it also guarantees extraordinary mechanical durability without any increase in resistance even after the bending was repeated for 1000 times. Besides, even when the folded edges of the battery cells based on their electrode architectures were repeatedly hammered, the light-emitting diode (LED) did not flicker.

A lithium-ion battery is a type of rechargeable battery in which lithium ions move from the negative electrode to the positive electrode during discharge and back when charging. A conventional electrode includes an active material, conductive agent, and binder, with metal foil used as a current collector.

The copper foil and aluminum foil are the current collector materials that are most commonly used in negative electrodes and positive electrodes. However, because these two exhibit high stiffness, extreme bending or even folding may result in overall conductivity decrease.

Professor Son and his research team solved such issues using insulating polymer substrates, such as polyethylene terephthalate (PET) films. The PET mats are porous, flexible, and posess a large surface area. This allowes strong adhesion of active materials on support layers than that of the smaller surface area, thereby greatly increasing the battery capacity.

In the study, the research team demonstrated the current-collector-free and binder-free nanowire-around-microfiber (NW@MF) architectures to allow LIBs to be superflexible and to provide capacity scaling flexibility for manufacturing LIBs. Both NW@MF architectures were fabricated using the ultrasonic spray method.

“The results of this study suggest that the NW@MF-based electrode architectures presented herein can be applied in other flexible electronic devices,” says Professor Son.

This study has been supported by the Ministry of Trade, Industry and Engery (MOTIE), the Ministry of of Science, ICT and Future Planning (MSIP), and the Ministry of Education (MOE), South Korea.

Journal Reference

Chihyun Hwang, et al., “Foldable Electrode Architectures Based on Silver-Nanowire-Wound or Carbon-Nanotube-Webbed Micrometer-Scale Fibers of Polyethylene Terephthalate Mats for Flexible Lithium-Ion Batteries,” Advanced Materials, (2018).