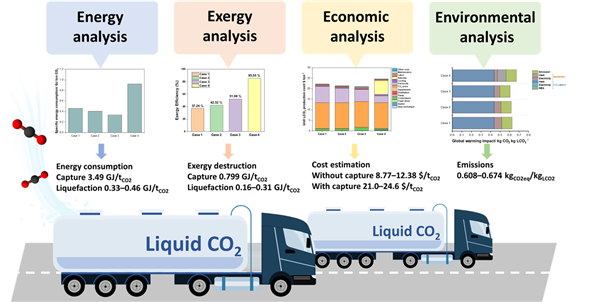

A research team, led by Professor Hankwon Lim (Graduate School of Carbon Neutrality) in the School of Energy and Chemical Engineering at UNIST carried out a comprehensive assessment in terms of 4E (Energy, Exergy, Economic, and Environmental)’s analysis of CO2 liquefaction in conjunction with the production of blue hydrogen.

According to the research team, the current study provides the insights of carbon capture and liquefaction (CCL) from flue gas. They further noted that this is the very first study which discusses the technical, thermodynamic, economic, and environmental aspects of CCL process. In addition, analytic hierarchy process (AHP) was also performed to provide comprehensive guidelines of liquefied CO2 production under technical, economic, and environmental aspects.

A thorough analysis has been conducted in this study from various perspectives, which in turn help assist the overall benchmark of an eco-friendly process that is energy efficient economical, and environmentally benign. The process analysis section is divided into four subsections, namely 4E (Energy, Exergy, Economic, Environmental), as well as Analytic hierarchy process (AHP) analysis.

Figure 1. Schematic image, describing the process analysis to achieve pure and liquefied CO2.

Hydrogen (H2) has attracted considerable attention as an energy carrier for future energy goals to replace fossil–fuel based energy system. The major source of H2 is reforming of natural gas, which results in huge amounts of CO2 emissions. However, the integration of the H2 production together with the carbon capture facility has been designated as emerging approach as a workable alternative. Consequently, the utilization of captured CO2 has been suggested as viable solution for mitigating the climate change. Therefore, storage and transportation of captured CO2 is one of the most crucial factors to be considered for sustainable solutions.

In this regard, technical, economic, and environmental assessments were made for an integrated carbon capture and liquefaction process to provide the basic insights. As a result, energy and exergy analysis of proposed processes demonstrate that the case 4 reflects minimum specific energy consumption (0.188el and 0.733th GJ/ton) with exergy efficiency of 85.55 %. Moreover, unit LCO2 production was calculated as 22.19, 21.35, 21.00, and 24.60 $ ton-1 for cases 1, 2, 3, and 4, respectively, in a result of economic evaluation. The climate change impacts were quantified as 0.629, 0.620, 0.608. and 0.674 kg CO2-eq kg LCO2-1 for cases 1, 2, 3, and 4, respectively. Therefore, it can be concluded that case 3 can become a satisfactory alternative for CO2 liquefaction in terms of technical, economic, and environmental perspectives at once.

The findings of this research have been published in the online version of Applied Energy on February 15, 2023. This study has been supported by the Carbon Neutrality Demonstration and Research Center of UNIST.

Journal Reference

Changgwon Choe, Junaid Haider, Hankwon Lim, “Carbon capture and liquefaction from methane steam reforming unit: 4E’s analysis (Energy, Exergy, Economic, and Environmental),” Applied Energy, (2023).