A research team, jointly led by Professors Jiyun Kim, Chaenyung Cha, and Myoung Hoon Song from the Department of Materials Science and Engineering at UNIST, has unveiled the world’s first flexible, biodegradable bioelectronic paper with homogeneously distributed wireless stimulation functionality for simple personalization of bioelectronic implants. These innovative materials are made from nanoscale functional materials, and thus can be further customized using simple methods, such as rolling, cutting, inward folding, and outward folding without losing functionalities. The research team expects that these results with unprecedented design flexibility can lay a foundation for the low-cost, simple, and rapid personalization of temporary bioelectronic implants for minimally invasive wireless stimulation therapies.

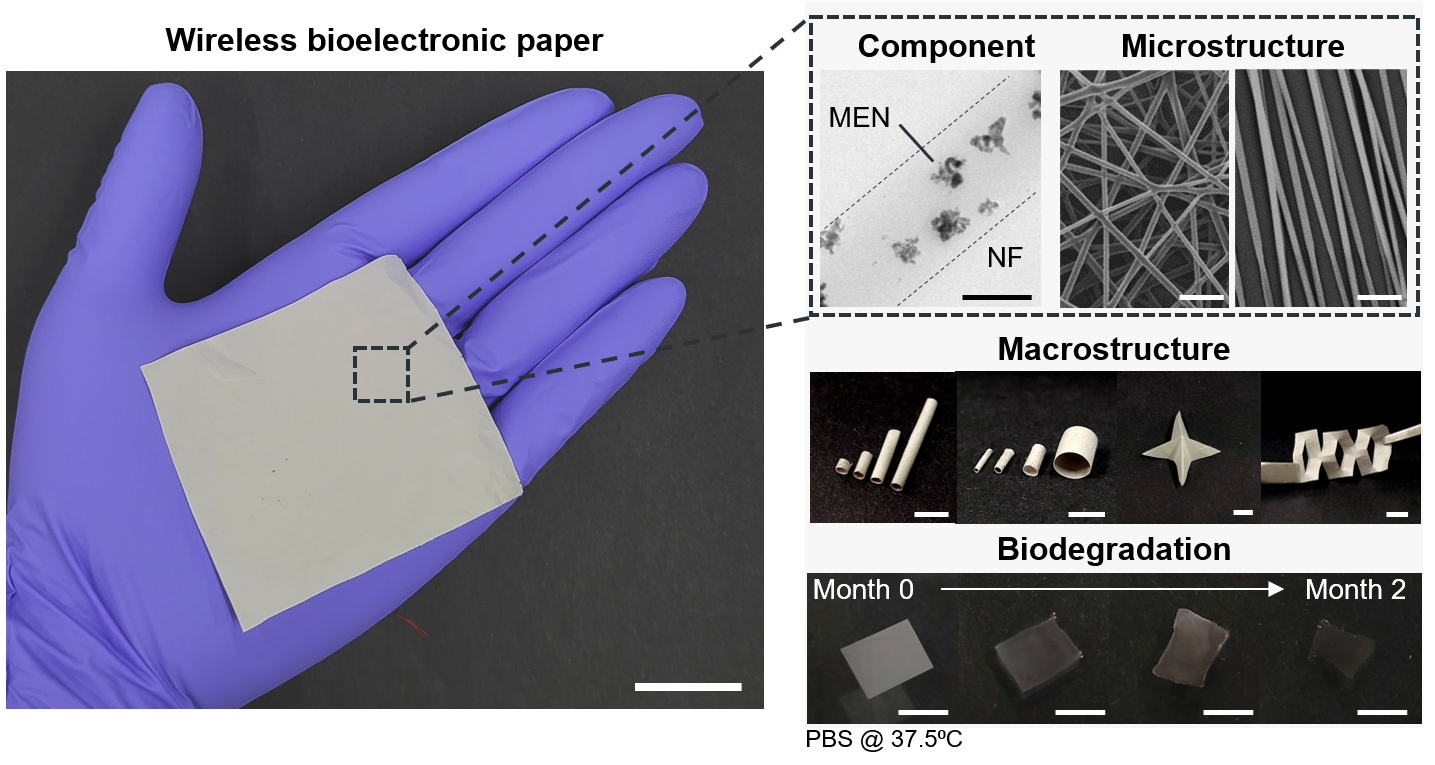

Figure 1. Shown on the left is the photograph of the implantable, wireless bioelectronic paper (thickness ≈50 µm; scale bar, 3 cm), fabricated via integrating MEN into NF. The microstructure of the bioelectronic paper can be designed to random or aligned fiber orientation. Shown on the right are photographs of the bioelectronic paper tailored into various macrostructures and scales using simple rolling, origami, and kirigami techniques. Sequential images showing dissolution of the bioelectronic paper during immersion in PBS at 37.5 °C.

Figure 1. Shown on the left is the photograph of the implantable, wireless bioelectronic paper (thickness ≈50 µm; scale bar, 3 cm), fabricated via integrating MEN into NF. The microstructure of the bioelectronic paper can be designed to random or aligned fiber orientation. Shown on the right are photographs of the bioelectronic paper tailored into various macrostructures and scales using simple rolling, origami, and kirigami techniques. Sequential images showing dissolution of the bioelectronic paper during immersion in PBS at 37.5 °C.

Implanted electrical stimulation devices are crucial for promoting neuronal activity and tissue regeneration through electrical stimulation. Therefore, these devices are essential for treating various neurodegenerative diseases, such as Parkinson’s disease and Alzheimer’s disease. However, most of the state-of-the-art bioelectronic implants require rigid and bulky electronics that are mechanically incompatible with the delicate structure of nerves and other tissues, making it difficult to freely change into various sizes and shapes in real time. In addition, the need for wire connections, battery replacement, and post-treatment removal surgeries can raise the risk of infection and make clinical treatments complex.

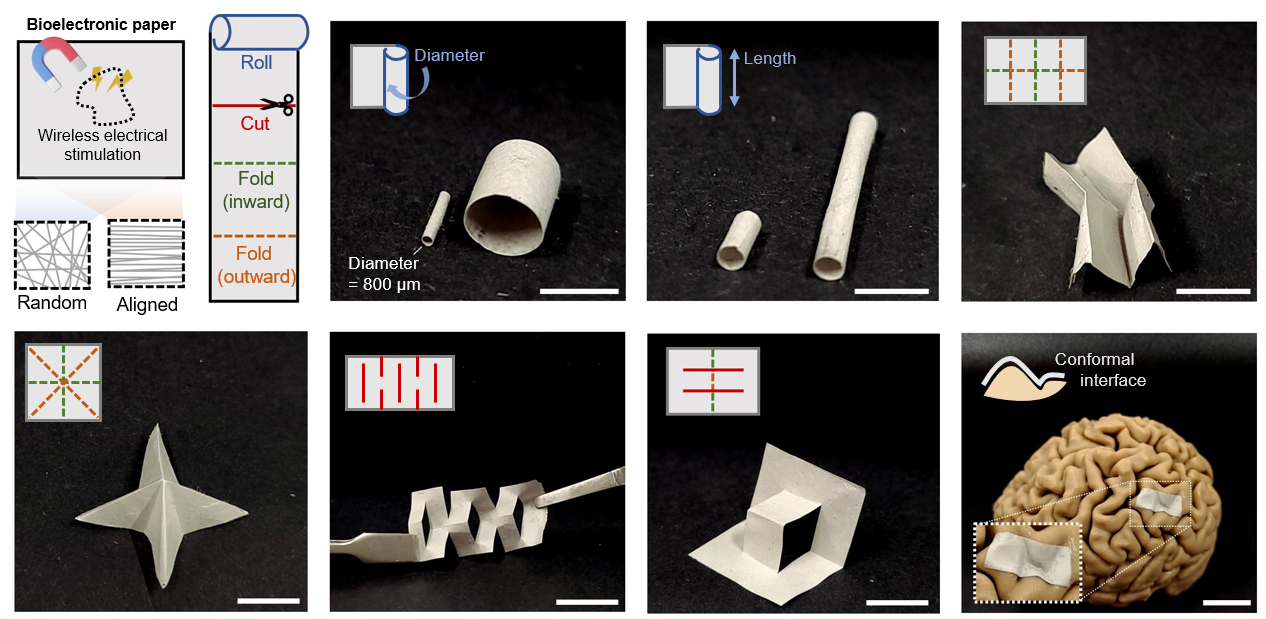

In this study, the research team successfully developed a flexible, biomimetic, lightweight, and biodegradable bioelectronic paper that can be cut and tailored post-fabrication while retaining functionalities, allowing for simple and rapid production of bioelectronic implants of various sizes, shapes, and micro- and macro-structures.

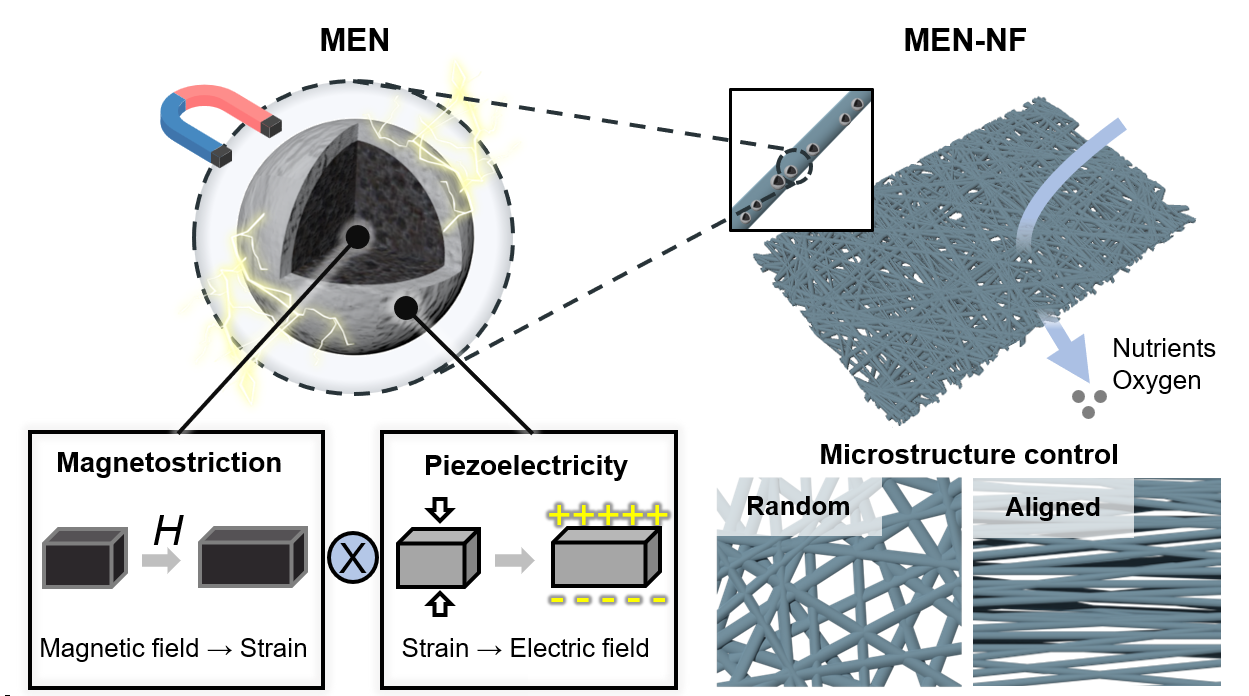

First, they synthesized magnetoelectric nanoparticles (MENs) that facilitate electrical stimulation in response to external magnetic field. The synthesized nanoparticles take the form of ‘Core@Shell’ structure that couples magnetostrictive core that transduces magnetic field into local strain and piezoelectric shell that transduces strain into electric field. By integrating MENs into electrospun biodegradable nanofibers (NFs), they produced a paper-like, biodegradable, porous wireless electrostimulator. In vitro experiments further demonstrated the material’s ability to provide wireless electrostimulation and promote neuronal activity simultaneously.

Figure 2. Schematic illustration of MEN synthesized in core/shell structure that couples magnetostrictive core that transduces magnetic field into local strain and piezoelectric shell that transduces strain into electric field. The MEN-NF has high porosity that allows permeation of small molecules and controllability in microstructural fiber orientations.

Figure 2. Schematic illustration of MEN synthesized in core/shell structure that couples magnetostrictive core that transduces magnetic field into local strain and piezoelectric shell that transduces strain into electric field. The MEN-NF has high porosity that allows permeation of small molecules and controllability in microstructural fiber orientations.

“The developed material offers personalized treatment options tailored to individual needs and physical characteristics, simplifying treatment processes, enhancing flexibility, and versatility in electrical stimulation-based clinical applications,” says Postdoctoral Researcher and First Author Jun Kyu Choe.

The fabricated material is as flexible and lightweight as paper. It can be closely attached along complex surfaces, like the curved surface of human brain models. Notably, it also can be cut into arbitrary shapes and scales, while retaining its function. Furthermore, it showed exceptional flexibility enough to manufacture a cylindrical nerve conduit to regenerate nerves, with a demonstrated bending radius of 400 µm.

Figure 3. Schematic images, showing the macrostructure programming of MEN-NF bioelectronic paper.

Figure 3. Schematic images, showing the macrostructure programming of MEN-NF bioelectronic paper.

According to the research team, “This work presents a promising strategy for the development of flexible and biodegradable wireless bioelectronic implants that can be simply customized for various clinical and physical circumstances.” They further noted, “The combination of nanoscale magnetoelectric and biodegradable fibrous materials offers advantages over traditional system-level wireless electronic devices that rely on intricate assembly of bulky components that cannot be redesigned post-fabrication.”

“The bioelectronic paper, in principle, can be simply customized to organ-scales of several tens of centimeters or miniaturized to sub-micrometer scales for minimally invasive operations, as the magnetoelectricity or microstructure does not depend on its scale.” noted Professor Kim. “Overall, our bioelectronic paper with facile and broad applicability, could open up a new scheme toward minimally invasive, and biodegradable wireless bioelectronic implants.”

The study, involving Dr. Jun Kyu Choe, Dr. Suntae Kim, and Dr. Ah-young Lee as first authors, was officially published in Advanced Materials on May 2, 2024. Their findings have been selected as an Inside Back Cover feature. The research received support from the National Research Foundation (NRF) of the Ministry of Science and ICT.

Their findings have been featured as Inside Back Cover of Advanced Materials on May 2, 2024.

Journal Reference

Jun Kyu Choe, Suntae Kim, Ah-young Lee, et al., “Flexible, Biodegradable, and Wireless Magnetoelectric Paper for Simple In Situ Personalization of Bioelectric Implants,” Adv. Mater., (2024).