A groundbreaking control technology has been developed to enable robotic arms to manage sudden heavy loads without excessive vibrations. This innovative solution can be implemented instantly through a simple software update to existing industrial robot controllers—used in over 90% of manufacturing facilities worldwide.

Researchers, led by Professor Sanghoon Kang from the Department of Mechanical Engineering at UNIST announced the successful development of an adaptive proportional-integral-derivative (PID) control algorithm, capable of maintaining stable operation even under abrupt load changes or external impacts.

PID controllers serve as the brain of robotic arms, calculating the force needed to follow a desired trajectory in real time. Due to their simplicity and proven reliability, they are the dominant control method in industrial robotics. However, conventional PID systems lack flexibility. They rely on fixed parameters, making them vulnerable to malfunctions or vibrations if the load suddenly varies or the robot encounters external contact.

To overcome this limitation, the research team developed an algorithm that enables robots to automatically fine-tune their control parameters in real time based on error feedback. Unlike traditional adaptive PID systems, their approach is specifically engineered to counteract the minute signal noise—called quantization errors—generated by digital sensors in robot joints. Previous adaptive algorithms often overreacted to this noise, causing unnecessary force adjustments and system instability.

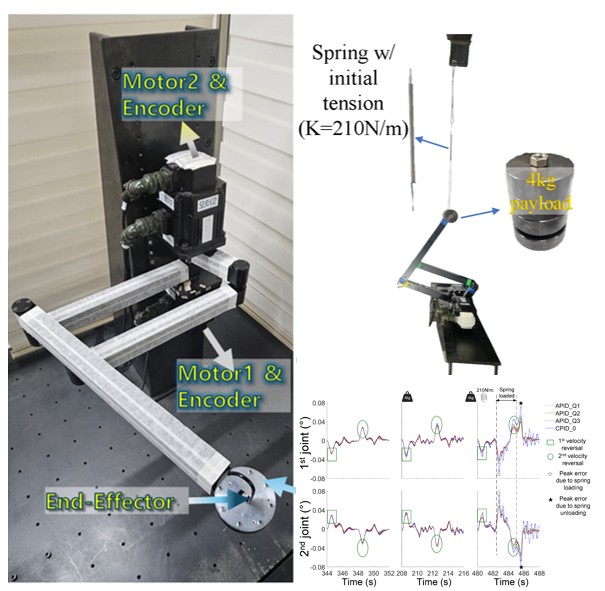

Figure 1. Experimental setup of a planar two-DOF direct-drive five-bar robot with hardware and software architecture and kinematic structure. A hook in end-effectors allows the robot to be connected with external dynamics.

Figure 1. Experimental setup of a planar two-DOF direct-drive five-bar robot with hardware and software architecture and kinematic structure. A hook in end-effectors allows the robot to be connected with external dynamics.

A key advantage of this new technology is that it requires only a software update—no hardware modifications, complex parameter inputs, or costly additional sensors are necessary. Any robot equipped with a PID controller can adopt this algorithm immediately.

The team demonstrated the effectiveness of the algorithm on a two-joint robotic arm under challenging conditions, such as lifting weights equal to its own mass and operating in environments with complex spring mechanisms. Results showed that the robot could adaptively adjust its control parameters to follow precise trajectories, despite environmental disturbances. In contrast, traditional control methods exhibited larger positional errors and instability.

Professor Kang remarked, “This development offers a significant enhancement in the performance of PID controllers, which are prevalent in industrial automation. It has broad potential applications—from smart factories with dynamic work environments to rehabilitation robots that respond to subtle human forces, and even humanoid robots.”

The findings of this research have been published in the January 2026 issue of IEEE/ASME Transactions on Mechatronics, one of the most respected journals in the fields of mechanical and robotic engineering.

This work was supported through the Future Promising Fusion Technology Pioneer Project by the National Research Foundation of Korea (NRF) and by the National Rehabilitation Center (NRC).

Journal Reference

Jeongwoo Son, Hyunah Kang, Murim Kim, et al., “Robust Adaptive PID Control Based on a Modified Nussbaum Function for Robots Exposed to Significant Changes in Dynamics,” TMECH, (2025).