An international team of researchers, affiliated with UNIST has introduced a new method to convert inexpensive polycrystalline metal foils to single crystals with superior properties.

Published in the online edition of Science on October 19, industrial scale production of single-crystal metal foils would now be possible from this discovery.

This breakthrough has been led by Distinguished Professor Rodney S. Ruoff (School of Natural Sciences) from the Center for Multidimensional Carbon Materials (CMCM), within the Institute for Basic Science (IBS) at UNIST in collaboration with Distinguished Professor Feng Ding (School of Materials Science and Engineering) from CMCM, Professor Hyung-Joon Shin (School of Materials Science and Engineering, UNIST), and Professor Won Jong Yoo from SKKU Advanced Institute of Nano-Technology (SAINT) of Sungkyunkwan University.

▲ Interview with Rodney S. Ruoff, Director of the Center for Multidimensional Carbon Materials (CMCM) at the Institute for Basic Science (IBS) and Distinguished Professor in the School of Natural Science at UNIST.

The structure of most metal materials can be thought of as a patchwork of different tiny crystals, bearing some defects on the borders between each patch. These defects, known as grain boundaries (GBs), worsen the electrical and sometimes mechanical properties of the metal. Single crystal metals, instead, have no GBs and show higher electrical conductivity and other enhanced qualities that can play a major role in multiple fields, such as electronics, plasmonics, and catalysis, among others. Single crystal metal foils have attracted great attention also because certain single crystal metals, such as copper, nickel, and cobalt, are suitable for the growth of defectless graphene, boron nitride, and diamond on top of them.

Single crystals are normally fabricated beginning with a ‘crystal seed’. Conventional approaches, such as the Czochralski or Bridgman methods, or others based on the deposition of thin metal films on single crystal inorganic substrates, achieve small single crystals at high processing costs.

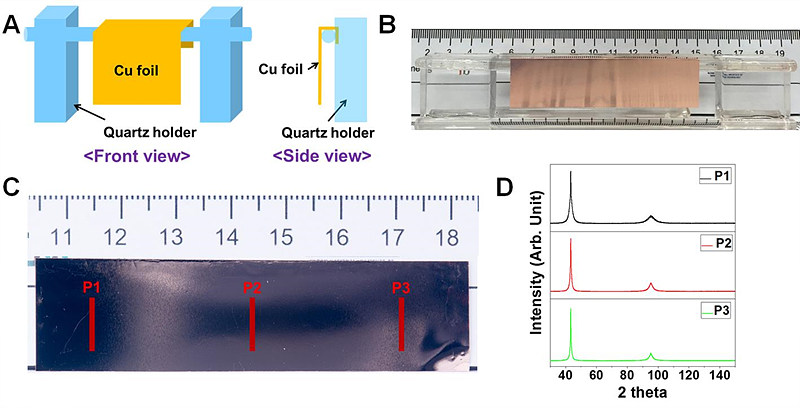

To unlock the full potential of such metal structures, the research team invented the “contact-free annealing” (CFA) technique. CFA involves heating the polycrystalline metal foils to a temperature slightly below the melting point of each metal. This new method does not need single crystal seeds or templates, which limit the maximum crystal size, and was tested with five different types of metal foils: copper, nickel, cobalt, platinum, and palladium. It resulted in a ‘colossal grain growth’, reaching up to 32 square centimeters for copper.

Schemic image, showing a single crystal copper foil produced by contact-free annealing.

The scientists also achieved single crystals from nickel and cobalt foils, each about 11 ㎠. The achieved sizes are limited by the size of the furnace, so that one could expect production of larger foils with ‘industrial’ processing methods.

For platinum, resistive heating was used because of its higher melting temperature (2041 K). Current was passed through a platinum foil attached to two opposing electrodes, then one electrode was moved and adjusted to keep the foil flat during expansion and contraction. The research team expects this trick to work for other foils, because it also worked for palladium.

These large single crystal metal foils are useful in several applications. For example, they can serve to grow graphene on top of them: the group obtained very high quality single crystal monolayer graphene on single crystal copper foil, and multilayer graphene on a single crystal copper-nickel alloy foil.

Figure 2. Graphene sheets grown on top of single crystal copper foil.

▲ (Left) Very high quality single crystal monolayer graphene was obtained on single crystal copper foil, and (right) multilayer graphene (from 2 to 10 layers) on a single crystal copper-nickel alloy foil.

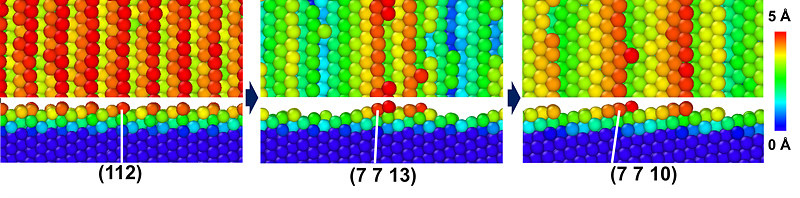

Figure 3. Crystals change orientation to minimize surface energy.

▲ The research team contributed a model and theoretical calculations on ‘colossal grain growth’ that was observed and studied through experiments. Professor Shin drew attention to the importance of the initial ‘texture’ of the polucrystalline metal foils and the role this plays in colossal grain growth.

The new single crystal copper foil showed improved electrical properties. The collaborating researchers from Sungkyunkwan University measured a 7% increase in the room temperature electrical conductivity of the single crystal copper foil, compared to the commercially-available polycrystalline foil.

“Now that we have explored these five metals and invented a straightforward scalable method to make such large single crystals, there’s the exciting question of whether other types of polycrystalline metal films, such as iron, can also be converted to single crystals,” noted by Dr. Sunghwan Jin, the first author of the study and his advisor, Distinguished Professor Ruoff.

Distinguished Professor Ruoff enthusiastically concludes, “Now that these cheap single crystal metal foils are available, it will be tremendously exciting to see how they are used by the scientific and engineering communities!”

Distinguished Professor Rodney S. Ruoff (School of Natural Science) and his research team from the Center for Multidimensional Carbon Materials (CMCM), within the Institute for Basic Science (IBS) at UNIST.

Letizia Diamante

Science Writer and Visual Producer

T: +82-42-878-8260

E:letizia@ibs.re.kr

Notes for Editors

The online version of the original article can be found HERE.

Journal Reference

Sunghwan Jin et al., “Colossal grain growth yields single crystal metal foils by contact-free annealing”, Science (2018). DOI: https://doi.org/10.1126/science.aao3373