A research team affiliated with UNIST has unveiled a comprehensive design method for the development of solid-state batteries (SSBs), marking a significant advancement in the field of battery design.

Professor Sungkyun Jung and his research team from the School of Energy and Chemical Engineering at UNIST, in collaboration with Dr. Jinsoo Kim from the Korea Institute of Energy Research (KIER), have developed a design methodology and a general-purpose toolkit aimed at facilitating the implementation of high-energy-density SSBs, successfully completing performance validations.

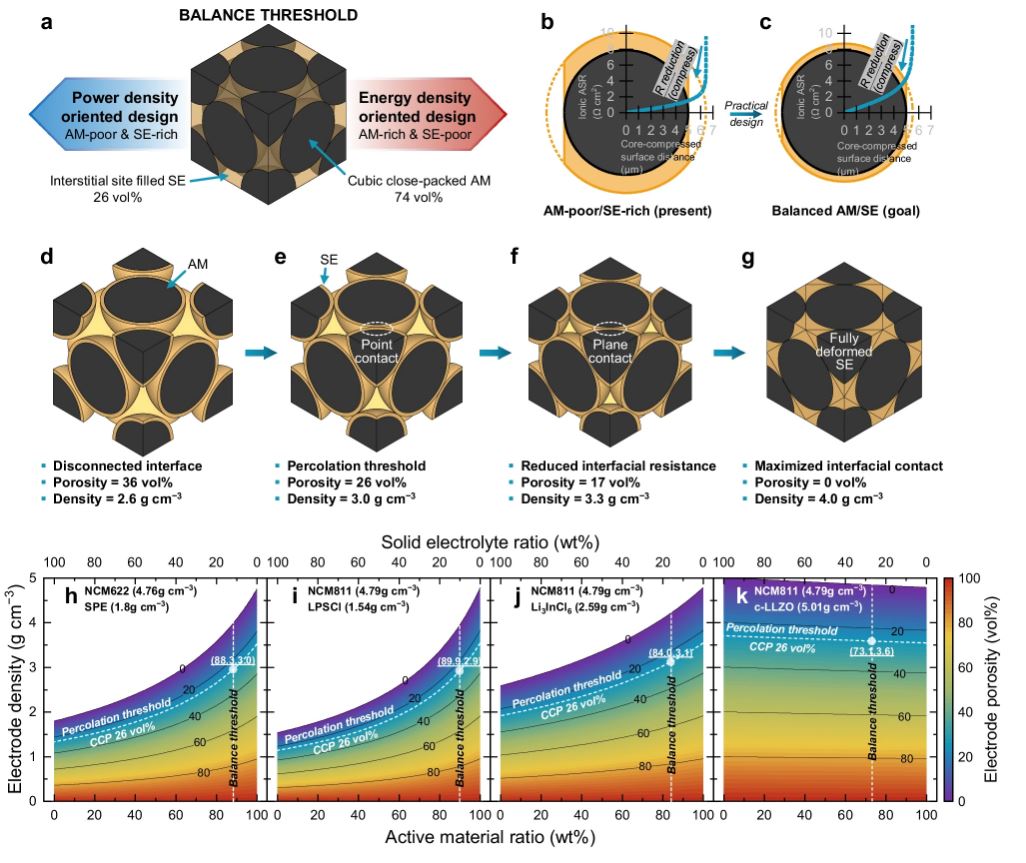

Figure 1. Particle composition and density design strategy for ideal SSB microstructure.

SSBs present a safe alternative to conventional lithium batteries by effectively addressing the flammability issues associated with liquid electrolytes. Through the utilization of solid electrolytes, these batteries eliminate fire risks and significantly enhance energy density via optimized design. However, much of the existing research has remained confined to laboratory settings, hampered by inefficient research and development processes due to the absence of clear scientific guidelines.

The research team identified three key thresholds essential for battery design and proposed the world’s first general-purpose methodology for SSB development. A pouch-type cell manufactured using this methodology achieved an energy density that surpasses that of commercial lithium batteries and has received certification from an accredited testing agency.

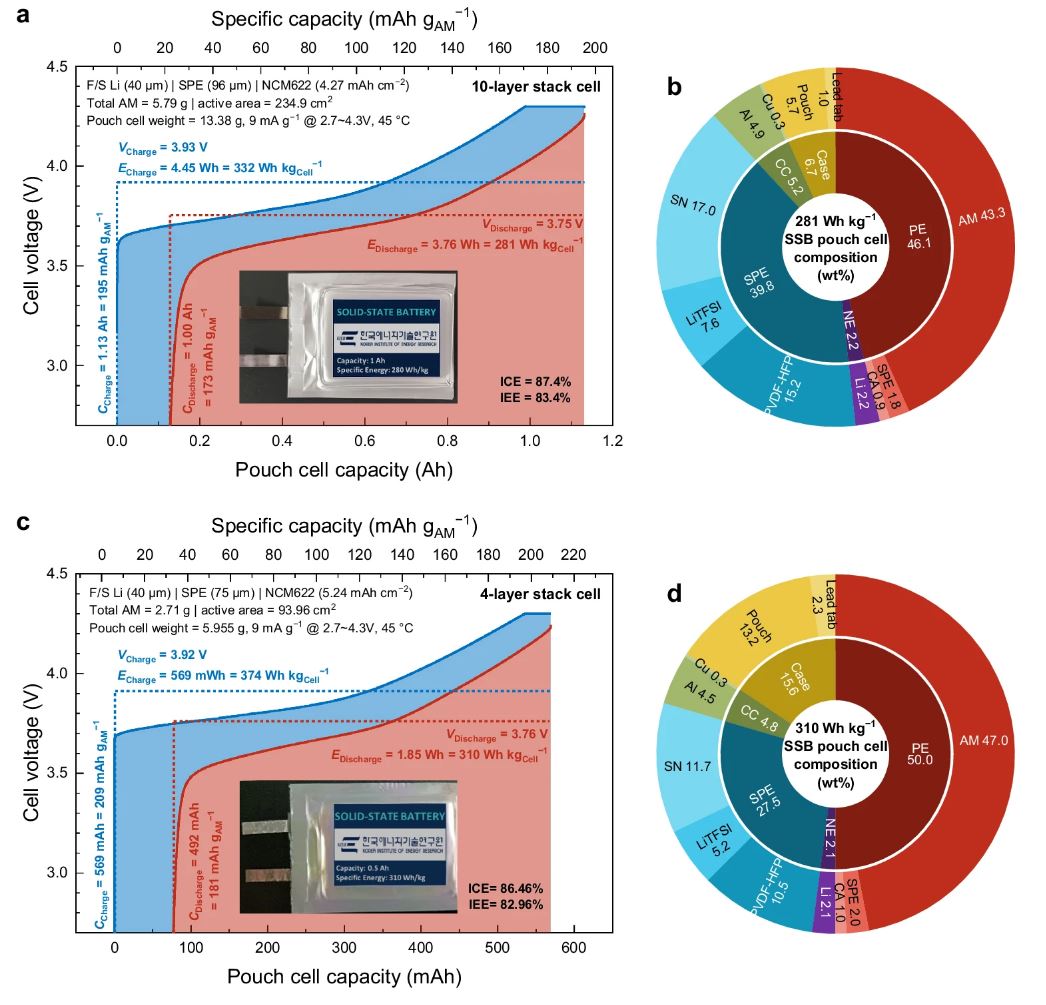

Figure 2. Electrochemical characteristics and compositions of practical SSB pouch cells.

The SSB consists of the cathode, anode, and solid-state electrolyte (SSE), with a higher energy density resulting from denser anode particles. To optimize this, the research team established a balance threshold, which defines the optimal structure for particle concentration, and adjusted the ratio of anode particles to solid electrolyte based on this value, allowing for diverse design variations.

Furthermore, the team defined the minimum density required for effective current flow as the “transmission threshold” and established the “load threshold” necessary for electrode thickness design. These parameters provide essential guidance for optimizing electrode design.

By utilizing this methodology, the team produced a pouch-type cell with an exceptional energy density of 310 Wh/kg at a capacity of 0.5 Ah, which has been officially certified by the Korea Conformity Laboratories (KCL). They also developed a toolkit called SolidXCell, designed for intuitive and systematic SSB design, which is being made available to researchers at no cost.

Professor Jung and Dr. Kim remarked, “This study will significantly aid in designing solid-state batteries, and we anticipate that many researchers will leverage this methodology to enhance battery performance.”

The findings of this research have been published in the July 2024 issue of Nature Communications. It has received support from the National Research Council of Science and Technology (NST) and the National Research Foundation of Korea (NRF).

Journal Reference

Wonmi Lee, Juho Lee, Taegyun Yu, et al., “Advanced parametrization for the production of high-energy solid-state lithium pouch cells containing polymer electrolytes,” Nat. Commun., (2024).