A research team led by Professor Jae Sung Lee and Professor Ji-Wook Jang from the School of Energy and Chemical Engineering at UNIST, in collaboration with the Tyndall National Institute from Ireland, has achieved a significant breakthrough in large-scale photoelectrode manufacturing. By utilizing fully automatic inkjet printing technology, this pioneering development marks the first successful application of inkjet printing for scale-up purposes in producing large photoelectrodes.

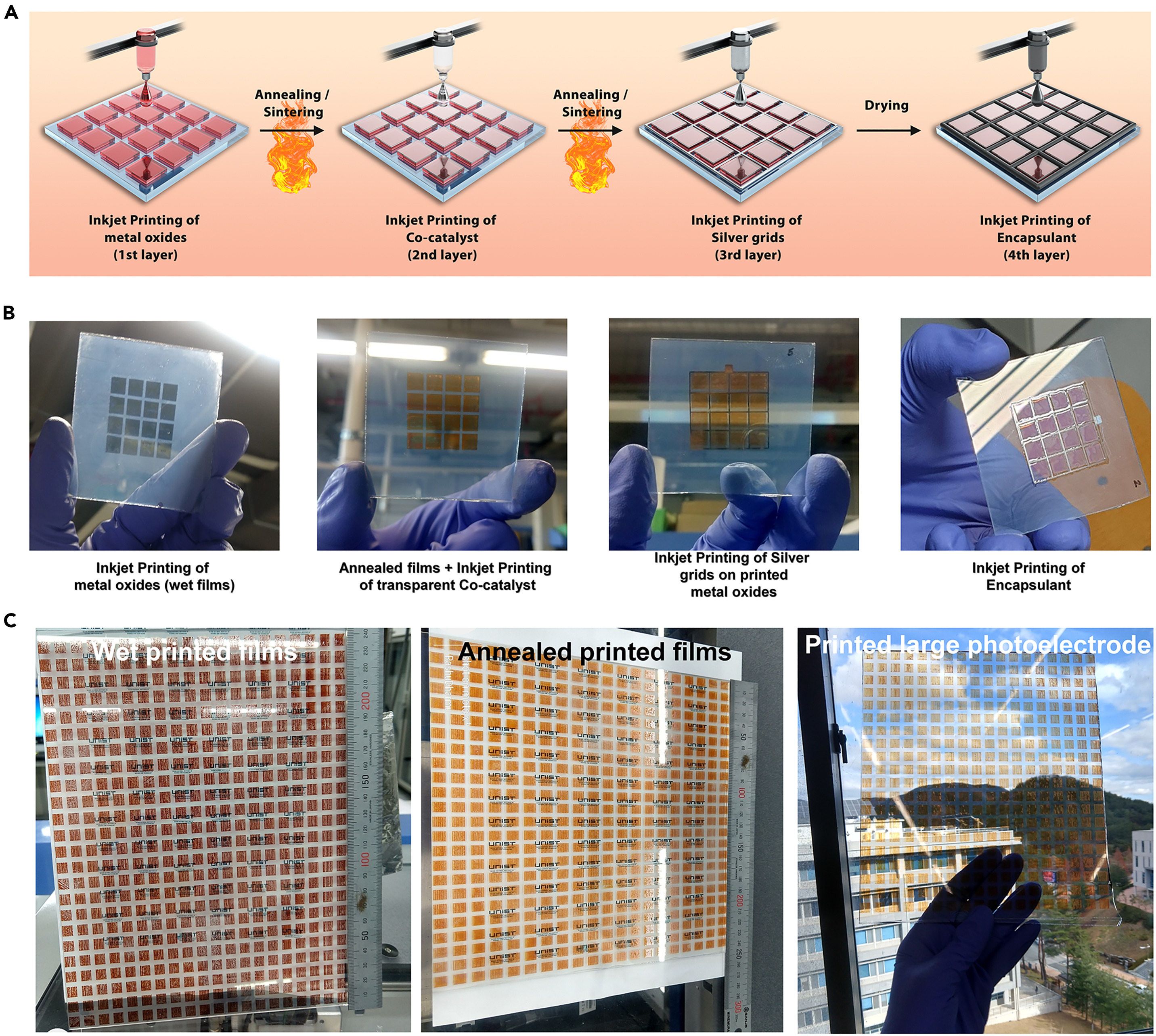

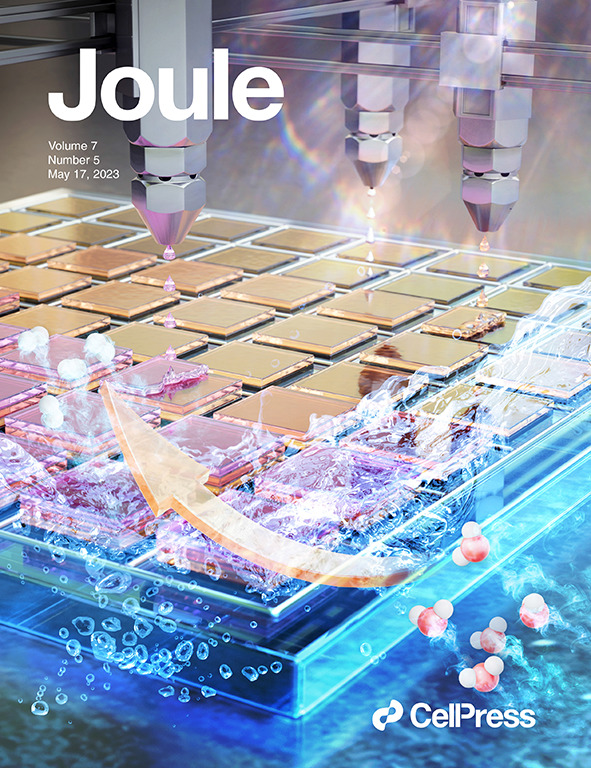

Figure 1. Protocol for fully inkjet-printed, thin-film large photoelectrodes for proof-of-concept. (A–C) IJP deposition steps for (A) cell-to-array module design fabrication by the deposition of metal oxides (1st layer) followed by annealing, then deposition of the cocatalyst (2nd layer) followed by sintering, deposition of Ag gridlines (3rd layer) followed by drying and a final deposition of transparent polymer encapsulant (4th layer) followed by room-temperature drying. Proof-of-concept of fully inkjet-printed Fe2O3 layers on an FTO glass substrate with basic designs for (B) small cells with a 4 × 4 array and photo-illumination area of 16 cm2, and (C) large photoelectrodes with 20 × 25 array and photo-illumination area of 500 cm2.

Solar hydrogen technology, which harnesses solar energy to decompose water and obtain hydrogen, is widely regarded as one of the most promising methods for green hydrogen production. However, its limited efficiency has hindered its competitiveness compared to conventional fossil fuel reforming processes.

The performance of photoelectrodes plays a crucial role in determining the overall efficiency and economics of solar hydrogen production systems. Typically, research-grade photoelectrodes are small-sized—often less than 1cm2. To achieve practical scales required for commercialization—around 1m2—a scale-up process that is 10,000 times larger becomes necessary. Historically, such scale-ups have resulted in decreased efficiency levels. Additionally, manual manufacturing methods employed within laboratories pose challenges when it comes to mass production suitable for widespread distribution.

To address these obstacles and pave the way towards commercializing solar hydrogen production systems on a larger scale, the research team turned to fully automatic inkjet printing technology as an innovative solution. Compared to vacuum-based processes used previously, this method offers enhanced cost-effectiveness while enabling precise and consistent printing of complex multilayered photoelectrodes with various functions over larger areas.

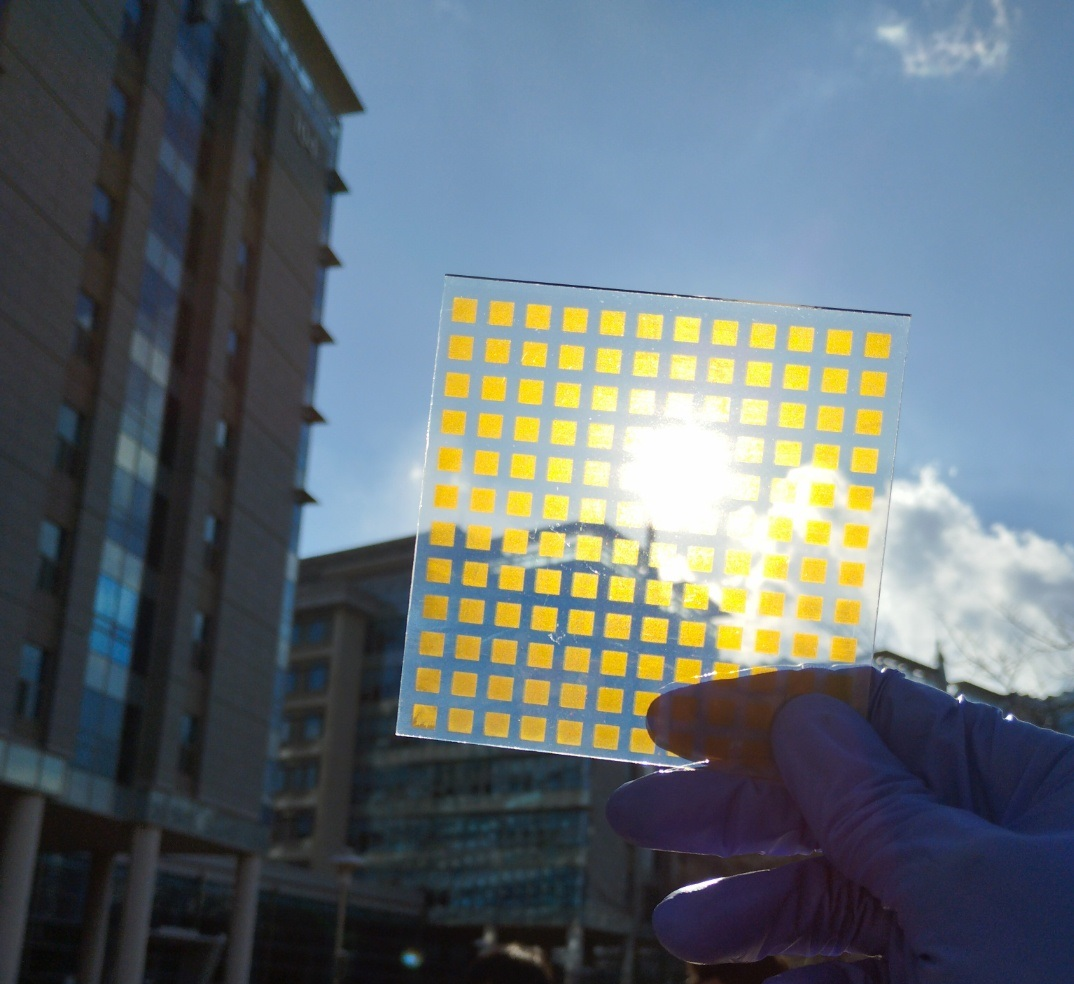

Figure 2. Fully inkjet-printed large-scale photoelectrodes. l Image Ciredit: UNIST

Thanks to their fully automated system’s high productivity without compromising performance quality or efficiency levels during fabrication tests using iron oxide photocatalytic electrodes as large-scale modules, the research team successfully demonstrated the efficacy of this technology. This achievement represents a significant milestone towards achieving commercial-scale production of solar hydrogen.

“The development of scalable photoelectrode manufacturing technology using inkjet printing brings us closer to realizing efficient and economically viable solar hydrogen production,” noted the research team. “This breakthrough opens up new possibilities for large-scale implementation and commercialization of solar hydrogen technology.” The study’s findings hold tremendous implications for advancing sustainable energy solutions and contribute significantly to global efforts in achieving a carbon-neutral future.

Their work has been selected for the cover feature of the May 2023 issue of Joule, a renowned journal published by Cell Press.

Their work has been selected for the cover feature of the May 2023 issue of Joule, a renowned journal published by Cell Press, with publication scheduled on May 17th, 2023. The collaboration involved Dr. Dennis Cherian from Tyndall National Institute in Ireland. Funding support was provided by the Climate Change Response Project and Brainlink Project through grants from Korea’s Ministry of Science and ICT.

Journal Reference

Dharmesh Hansora, Dennis Cherian, Rashmi Mehrotra, et al., “Fully inkjet-printed large-scale photoelectrodes,” Joule, (2023).