The ability to predict the feasibility of manufacturing parts significantly enhances production efficiency and reduces costs in the manufacturing industry. Leveraging this technology, the laboratory of the Department of Industrial Engineering at UNIST has developed an innovative AI-based prediction algorithm and achieved victory in an international competition.

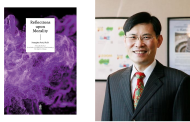

Gyeongho Kim, a Ph.D. student from the laboratory of Professor Sunghoon Lim, who is affiliated with the Department of Industrial Engineering and the Graduate School of Artificial Intelligence, won first place at the 2024 INFORMS QSR Manufacturing AI Case Study Competition, hosted by the Institute for Operations Research and The Management Sciences (INFORMS). This competition focuses on solving real-world industrial challenges utilizing actual manufacturing data.

The challenge involved predicting the manufacturability of a microbiological fuel cell (MFC) anode structure. Given three-dimensional (3D) structural information, the team was tasked with determining the feasibility of actual production.

Gyeongho Kim, a key contributor to the project, developed a machine learning-based prediction algorithm by analyzing the physical and geometric characteristics of the MFC anode structure. Additionally, he created a deep learning-based algorithm that leverages complex three-dimensional structural data.

The final predictive analysis employed an ensemble model that effectively combined both algorithms, achieving an impressive prediction accuracy exceeding 95%. These research findings are anticipated to have a significant impact on the design and optimization of MFC anode structures.

Gyeongho Kim stated, “We plan to transform the prediction technology developed in this project into an academic paper. If this technology is implemented in manufacturing environments, it could positively influence the industry as a whole.”

In a notable achievement, Gyeongho Kim was selected as the first recipient of the Presidential Science Scholarship in April 2024 and has authored over eight papers as the first author, focused on smart manufacturing and artificial intelligence applications in leading international journals.

![[2026 UNIST Matriculation] “Design Questions the World Has Never Seen!”](https://news.unist.ac.kr/wp-content/uploads/2026/02/사진-박종래-UNIST-총장이-2026년-입학식사를-전하고-있다-1-1-190x122.jpg)

![[2026 UNIST Commencement] “Become Way Makers Who Open Paths Where None Are Drawn!”](https://news.unist.ac.kr/wp-content/uploads/2026/02/사진-박종래-총장이-UNIST-학위수여식사를-전하고-있다-3-1-190x122.jpg)

![[2026 UNIST Commencement] Voices of Class of 2026](https://news.unist.ac.kr/wp-content/uploads/2026/02/Untitled1-190x122.jpg)